pipe cladding machines factory

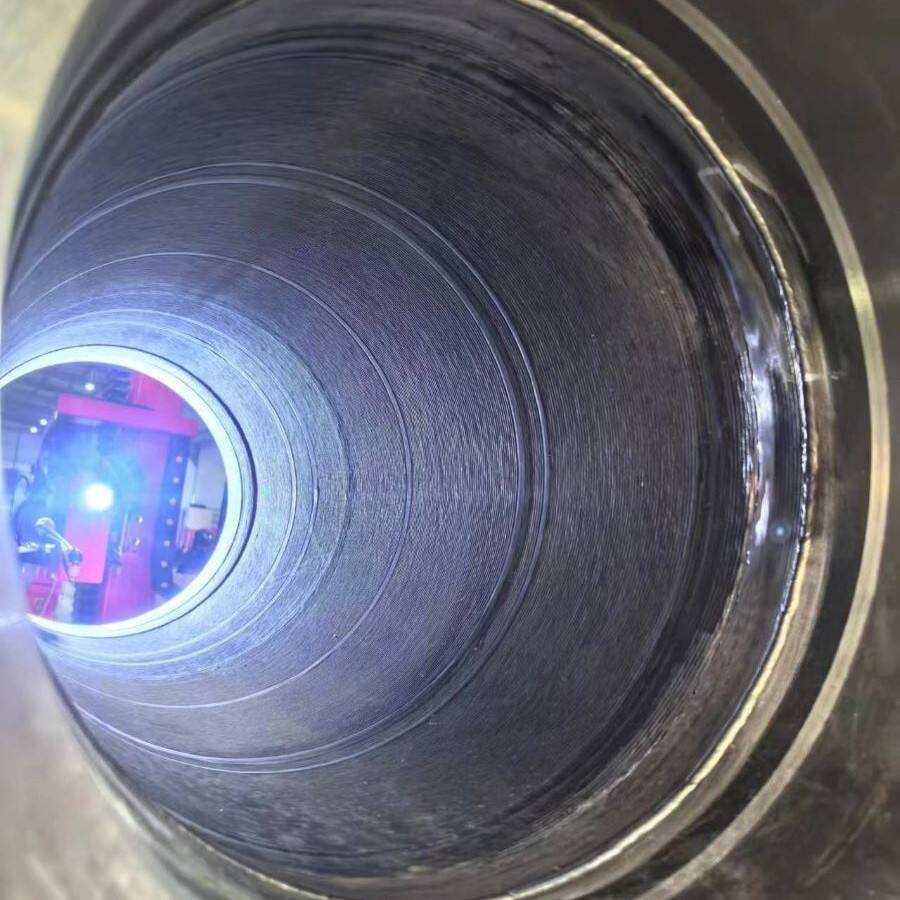

A pipe cladding machines factory represents a cutting-edge manufacturing facility dedicated to producing advanced equipment for pipe surface treatment and protection. These specialized facilities integrate state-of-the-art automation systems, precision engineering capabilities, and quality control measures to manufacture machines that apply protective layers to various types of pipes. The factory's production line encompasses multiple stages, from raw material processing to final assembly, utilizing advanced CNC machinery and robotics to ensure consistent quality. The facility specializes in creating machines capable of applying different cladding materials, including metallic alloys, polymers, and composite materials, to pipes of varying diameters and lengths. These machines incorporate sophisticated control systems that monitor and adjust cladding thickness, temperature, and application speed in real-time. The factory's operations are supported by research and development teams that continuously work on improving cladding technologies and developing new solutions for specific industry requirements. Quality assurance protocols are implemented at every production stage, ensuring that each machine meets international standards and specifications. The facility also maintains dedicated testing areas where completed machines undergo rigorous performance evaluations before shipment to customers.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LT

LT UK

UK SQ

SQ HU

HU TH

TH TR

TR FA

FA AF

AF CY

CY MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY