pipe cladding machines made in china

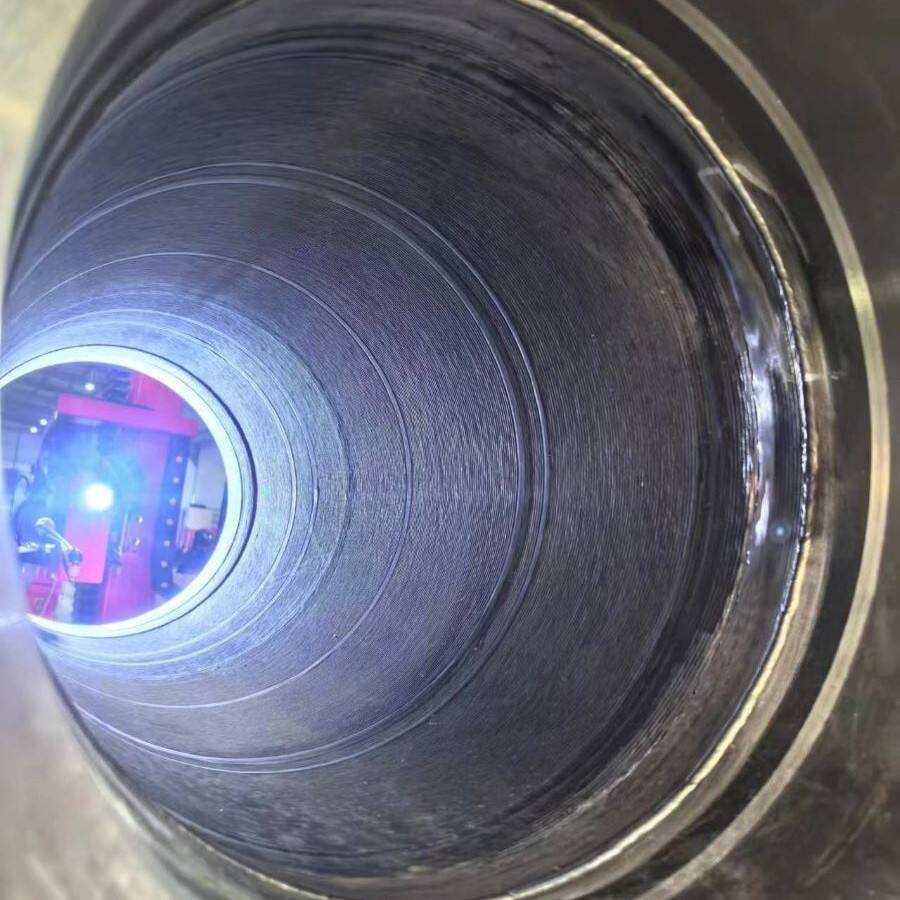

Pipe cladding machines made in China represent a significant advancement in industrial welding technology, offering sophisticated solutions for pipeline manufacturing and maintenance. These machines utilize advanced overlay welding techniques to apply protective layers on pipe surfaces, effectively enhancing corrosion resistance and extending service life. The machines feature state-of-the-art digital control systems that ensure precise deposition rates and consistent weld quality. They incorporate multiple welding heads capable of simultaneous operation, significantly improving production efficiency. The equipment supports various welding processes, including SAW, GMAW, and GTAW, making them versatile for different cladding requirements. Chinese manufacturers have integrated smart monitoring systems that provide real-time feedback on welding parameters, temperature control, and material feed rates. These machines can handle pipes ranging from 50mm to 1500mm in diameter, with adjustable rotation speeds and automated positioning systems. The technology includes advanced features such as automatic seam tracking, parameter optimization, and quality control mechanisms. Applications span across multiple industries, including oil and gas, petrochemical, power generation, and marine engineering, where high-performance corrosion-resistant piping is essential.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LT

LT UK

UK SQ

SQ HU

HU TH

TH TR

TR FA

FA AF

AF CY

CY MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY