pipe cladding machines

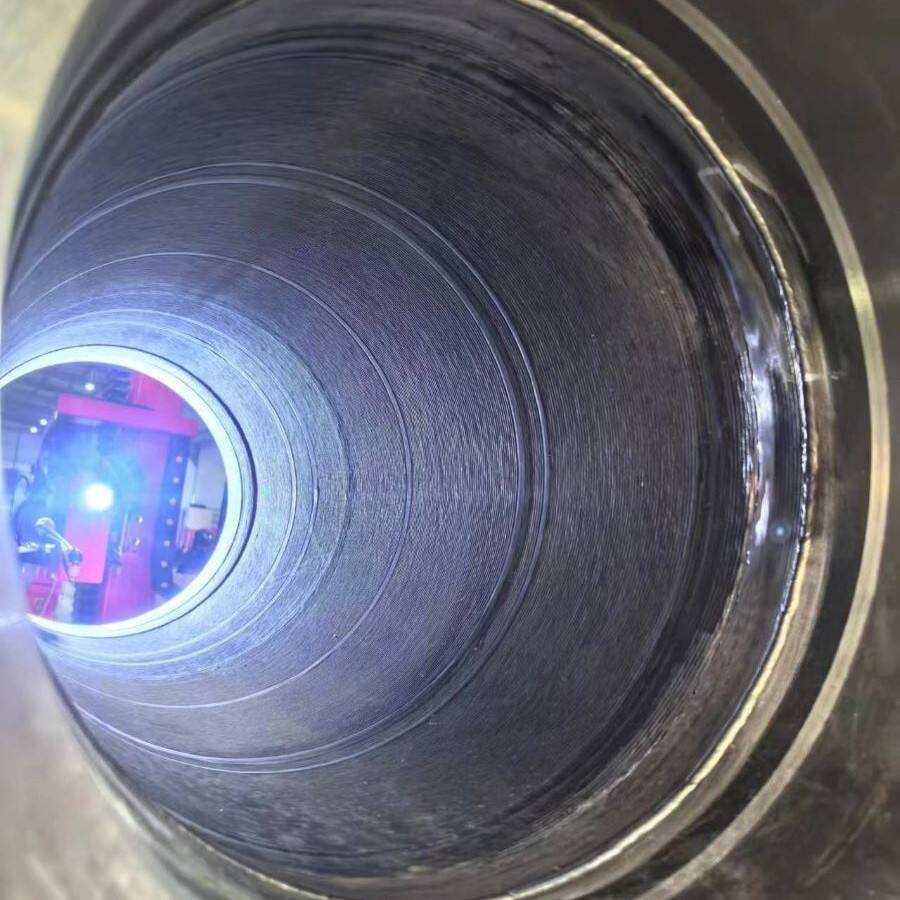

Pipe cladding machines represent cutting-edge technology in the metal fabrication industry, designed to apply protective or functional layers to pipe surfaces with exceptional precision and efficiency. These advanced systems utilize various welding processes, primarily automated overlay welding, to deposit corrosion-resistant alloys or wear-resistant materials onto base pipes. The machines feature sophisticated control systems that maintain consistent welding parameters, ensuring uniform cladding thickness and superior metallurgical bonding. Modern pipe cladding equipment incorporates real-time monitoring capabilities, allowing operators to track critical parameters such as temperature, feed rate, and material deposition. The machines can handle pipes of various diameters, typically ranging from 2 inches to 60 inches, and accommodate different cladding materials including stainless steel, nickel alloys, and other specialized metals. The process involves precise rotation of the pipe while the welding head deposits the cladding material in a carefully controlled pattern, creating a seamless protective layer. These systems find extensive applications in oil and gas, chemical processing, power generation, and marine industries where corrosion resistance and material durability are paramount.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LT

LT UK

UK SQ

SQ HU

HU TH

TH TR

TR FA

FA AF

AF CY

CY MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY