pipe cladding machines manufacturer

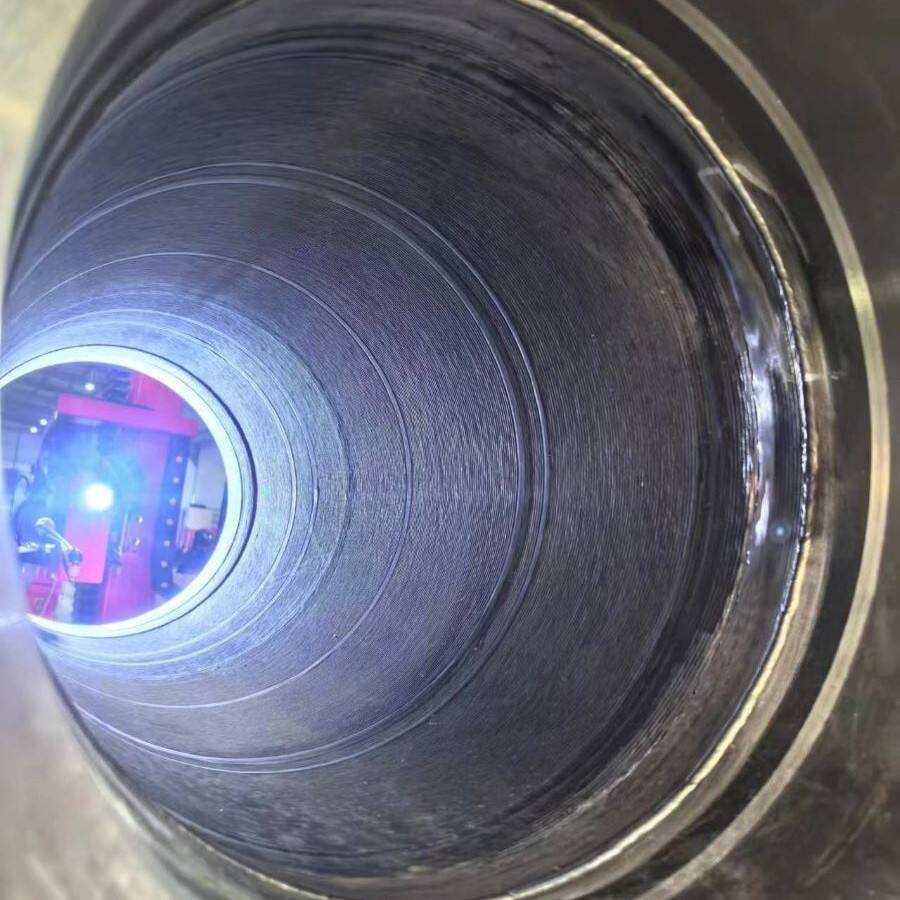

A pipe cladding machines manufacturer specializes in developing and producing advanced equipment for the precise application of protective layers onto pipes. These sophisticated machines utilize cutting-edge technology to deliver consistent, high-quality cladding solutions essential for various industries. The manufacturing process incorporates state-of-the-art welding techniques, including automated overlay welding systems and advanced control mechanisms, ensuring uniform coverage and superior bonding strength. These machines are designed to handle pipes of various diameters and lengths, making them versatile for different industrial applications. The manufacturer's expertise extends to both internal and external pipe cladding, offering comprehensive solutions for corrosion protection, wear resistance, and thermal insulation. The production facility employs rigorous quality control measures, advanced testing procedures, and automated monitoring systems to ensure each machine meets strict industry standards. These machines are equipped with precision control systems, allowing for accurate material deposition and consistent layer thickness, which is crucial for maintaining the integrity of the final product. The manufacturer also provides customization options to meet specific client requirements, supported by experienced engineering teams who offer technical consultation and after-sales support.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LT

LT UK

UK SQ

SQ HU

HU TH

TH TR

TR FA

FA AF

AF CY

CY MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY