china pipe cladding machines

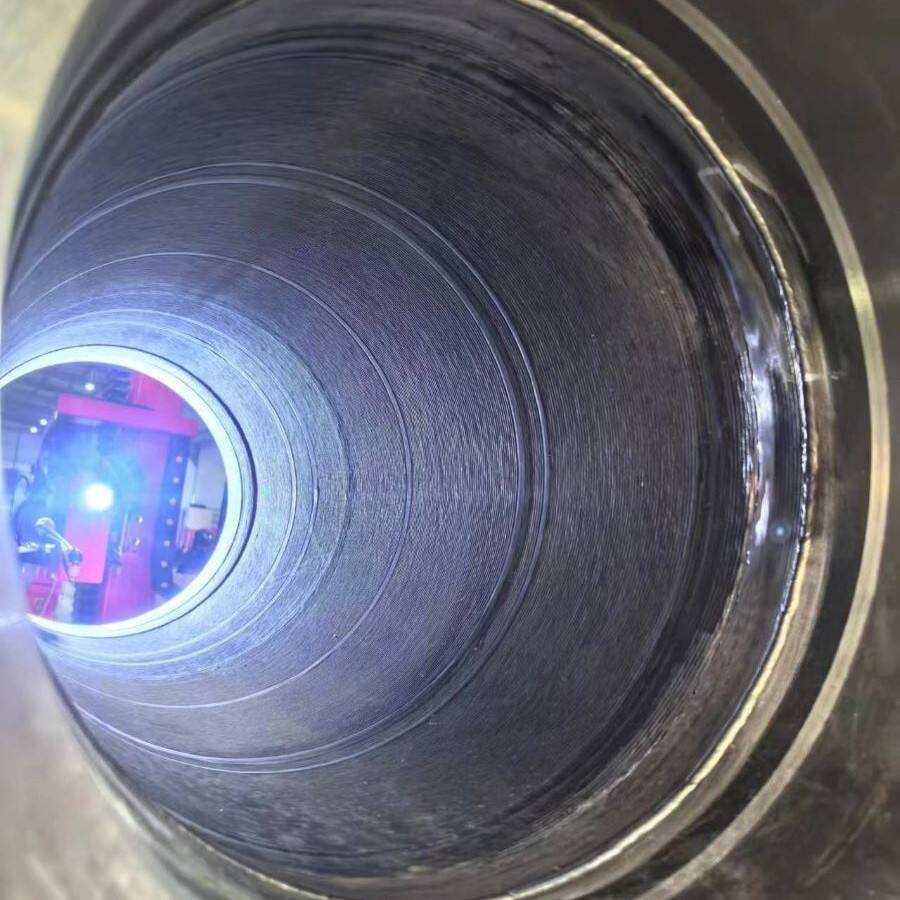

China pipe cladding machines represent cutting-edge technology in the pipe manufacturing industry, offering advanced solutions for applying protective layers to various types of pipes. These sophisticated machines utilize state-of-the-art welding and cladding techniques to deposit corrosion-resistant materials onto pipe surfaces, ensuring enhanced durability and performance. The machines are equipped with precise control systems that maintain consistent cladding thickness and quality throughout the process. They can handle pipes of different diameters and lengths, making them versatile for various industrial applications. The automated operation system incorporates multiple welding heads that work simultaneously, significantly improving production efficiency. These machines excel in both internal and external pipe cladding operations, featuring advanced monitoring systems that ensure quality control in real-time. The technology employs various cladding methods, including plasma transfer arc, hot wire TIG, and MIG processes, allowing for different material combinations and specific application requirements. Modern china pipe cladding machines also integrate smart control systems that enable remote monitoring and adjustment of parameters, ensuring optimal performance and consistent quality across production runs.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LT

LT UK

UK SQ

SQ HU

HU TH

TH TR

TR FA

FA AF

AF CY

CY MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY