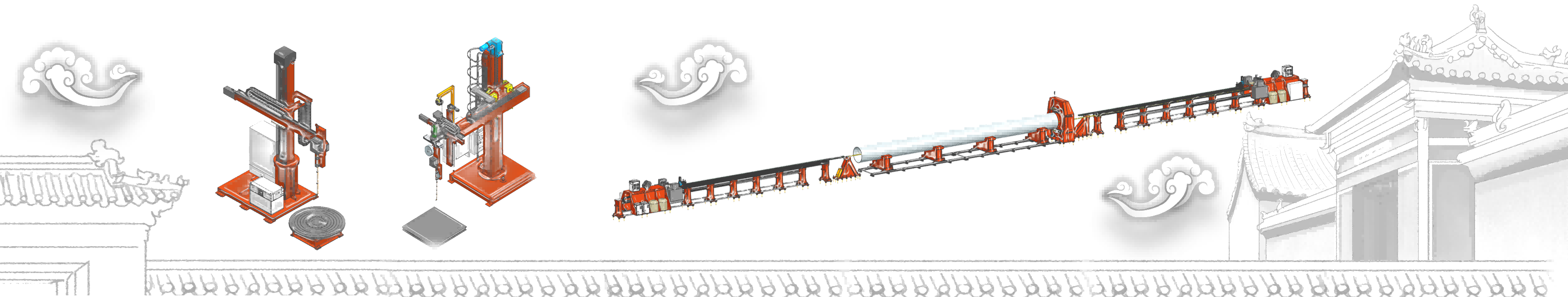

Gtaw+Saw Butt Welding Station

FIT-FAB-II-S-12M is a dual-purpose pipeline prefabrication welding station for argon arc and submerged arc. It is suitable for carbon steel, stainless steel, nickel-based alloy, cladding composite materials and other types of pipeline materials.

- Overview

- Recommended Products

Stability, efficiency, innovation and integrity are the principles that FITco adheres to. Our design principle is to ensure the stability of the equipment first, so we choose international first-class controllers, electrical components, welding power sources.Our equipment adopts the most advanced and most stable digital communication protocol Ethernet/IP, which ensures the stability and timely of the equipment internal communication, also reserves the most reliable interface and the most convenient communication protocol for users to achieve factory-level digitalization in the future. Ethernet/IP can be easily realized in the TCP/IP communication protocol information and data inter working, laying a solid foundation for the realization of real industry 4.0 and smart factory!

Fitco has grown and developed from a cladding and prefabricated products manufacturing plant, from the equipment maintenance department of the product manufacturing plant to a professional cladding and prefabrication equipment manufacturer, so we are more familiar with the problems that users may encounter, in addition to the equipment itself, our familiarity with the welding process is much higher than our competitors。

Key Parameters:

| Item | Technical Parameter | |

| Input Voltage | 380V±10% 50±1Hz Three-phase Five-wire | |

| Environment Temperature | -20℃~50℃ | |

| Workpiece Specification | Pipe Diameter | Φ200~1000mm |

| Length | 1000mm~12000mm | |

| Material | Carbon steel, alloy steel, stainless steel, low temperature steel, cladding composite materials, etc. | |

| Bevel Angle Requirement | Groove form V. Double V-shaped. U-shaped. I-shaped. Narrow gap U-shape, bevel angle 3~ 37.5° | |

| Weld Form | Various pipe sections butt girth weld seams and insert internal and external fillet weld seams, such as pipe - pipe, pipe - elbow, pipe - flange, pipe - tee, pipe - reducer, flange - pipe - flange, flange - elbow, etc. Flanges include: high neck flanges and flat welded flanges | |

| Welding Operating Machine | Column | Effective stroke: 3000 mm |

| Drive mode: servo motor + trapezoidal screw, linear guide rail | ||

| Boom | Effective stroke: 2000 mm | |

| Drive mode: servo motor + ball screw, linear guide rail | ||

| Base | Size : 1000 mmx1000mm | |

| Drive mode: frequency converter + roller + steel rail | ||

| Drive System | Drive Mode | Servo motor, reducer and roller drive the tube to rotate. |

| Load Capacity | Vertical bearing weight: 5 tons | |

| Max. Torque | ≥2000N.m | |

| Slewing speed | 0.05-2rpm, Stepless adjustable (3KW servo motor drive) | |

| Control System | Control Software | Apply Rockwell PLC control and Pro-Face hand operator HMI interface, the control software includes 10 sets of mature welding process programs, and the maximum storage of 50 sets of welding process programs. |

| Remote Control | Pro-Face/Delta hand operator HMI interface. | |

| Password | The control system can manage passwords to distinguish user permissions. | |

| Auto save and power failure memory | The system has automatic saving and power failure memory function, which can prevent the risk caused by power failure. | |

| Welding Power Source | Phoenix 650 puls argon arc, carbon dioxide shielded welding and submerged arc three-in-one welding power source with EtherNet/IP digital communication protocol produced by EWM | |

| Welding Parameter Setting Range | Workpiece speed 0-1000mm/ min, groove depth 5-30mm, welding swing 0-20mm, swing speed: 0~300mm/min, left and right stay about 0-3s. Presets and fine-tuning are available. | |

Welding Power Supply System

1.Phoenix 650 puls argon arc, carbon dioxide shielded welding and submerged arc three-in-one welding power source with EtherNet/IP digital communication protocol produced by EWM of Germany is used. GTAW: welding current: 5A-550A, duty cycle (40°C): 420A 100%; GMAW: welding current: 5A-550A, duty cycle (40°C): 420A 100%; SAW: welding current: 20A-650A, duty cycle (40°C): 590A 60%, 500A 100%.

2.The device is equipped with TETRIX 200 SMART HOT WIRE power source from EWM.

3.The independently developed water-cooled automatic GTAW welding gun has a rated current carrying capacity of 300A, which is durable and has good protection effect.

Camera Monitoring System (Optional)

The welding monitoring camera uses the special camera for strong light monitoring developed by our company. It is suitable for various industrial strong light monitoring occasions and can be used for various welding (MIG, MAG, GTAW, plasma, laser) arc strong light visual monitoring. The camera can clearly observe the dynamic changes in the arc light. With the relevant monitoring equipment system, operators in some special dangerous jobs can be liberated, and operators can clearly observe the operation situation even if they are far away from the dangerous area.

Product feature

1.Adopt high dynamic and low illumination imaging sensor, which can clearly image in super bright light area and corresponding dark light area.

2.Network digital output interface, with strong anti-interference ability, long transmission distance and good compatibility.

3.Compatible with ONVIF protocol, it can be connected to the monitoring system for remote viewing.

4.The device is compact and easy to install.

5.Wide power supply voltage DC9V-13V.

6.There is protective glass in front of the lens and spotlight, which can be removed and replaced.

After-Sales Support

We take full responsibility for providing professional after-sales technical services and genuine spare parts supply, ensuring your equipment operates smoothly throughout its lifecycle.

Product Warranty Commitment

We provide a 12-month quality warranty for all equipment, starting from the date of final acceptance and signature. This warranty covers equipment quality issues under normal usage conditions, with the exception of consumable parts and damages caused by human factors.

(i)Within the warranty period: If the equipment malfunctions due to inherent quality defects, we will provide free maintenance and repair services. For failures caused by improper operation, our technicians will respond promptly to resolve the issue, and reasonable service costs will be borne by the customer.

(ii)Important Note: The use of non-genuine spare parts or substitutes will result in the automatic termination of your warranty rights.

Lifelong Maintenance & Support

Our commitment doesn't end with the warranty. After the 12-month warranty expires, we continue to offer lifelong maintenance services for all our products. You can also enjoy preferential technical support for life, ensuring long-term value from your investment.

During the warranty period, we prioritize your production efficiency with a rapid response system:

(ii)Upon receiving your equipment fault notification, we will provide a response within 8 hours to guide troubleshooting.

(ii)If the issue cannot be resolved remotely, we will dispatch professional maintenance engineers to your site within 1 week to address the problem.

With our comprehensive after-sales support, you can focus on your core operations while we take care of your equipment needs. For any after-sales inquiries, feel free to contact our dedicated service team anytime

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LT

LT UK

UK SQ

SQ HU

HU TH

TH TR

TR FA

FA AF

AF CY

CY MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY