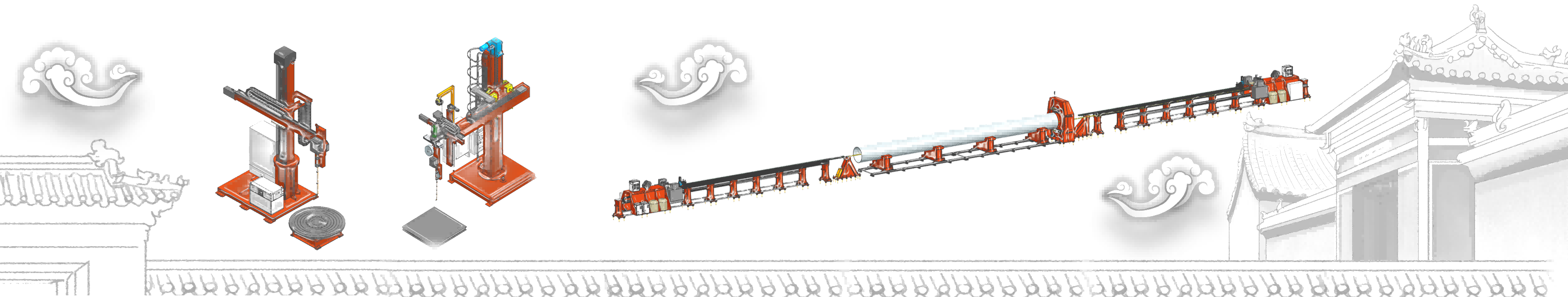

Container Integrated Horizontal Cladding Station

XHL-HCS Container Integrated Horizontal cladding station which is designed for heavy and complex shaped products for oil & gas, chemical, valve manufacturing, pressure vessels and other industries, the welding torch is designed to meet the requirements of a wide range of different shape products. This machine can be used for precision welding of corrosion-resistant materials and wear-resistant materials.

- Overview

- Recommended Products

- The welding power supply is powered by TETRIX 452 DC-type DC pulse arc welding power source produced by EWM , Germany.The welding maneuvering characteristics are good, the continuous operation is stable and reliable, and its pulse function meets the process requirements of welding.

- The TETRIX 200 HOT WIRE thermal wire power source from EWM is used.

- The use of self-developed water-cooled automatic TIG welding torch, rated current capacity of 300A, durable and reliable.

- Using Rockwell AB's latest generation PLC and servo system control, EtherNet/IP digital communication is used to control and monitor a wide range of input, output and sampling signals in high resolution;

- The system uses the Pro-face handheld touch screen, the display size 5.7 inch color screen, the interface is simple and easy to operate;

- The main electrical components of the equipment are imported brands in Europe and the United States;

- Real-time arc length tracking control;

- Parameter memory function, can be saved and printed in the welding process;

- The remote control enables real-time display, allowing the user to see various states in the process on the remote control;

- The welding process can manually adjust welding parameters such as current, speed, welding voltage, wire feed speed, hot wire current and whether to fill wire at any time to meet certain special requirements;

- The start-stop welding setting, including arc ingestion current, pre-ventilation time, delay wire delivery, arc current, delay stop wire and other settings;

- A friendly and intuitive programming interface that allows you to understand the welding process without the need for specialized personnel;

- Real-time display of welding voltage, welding current, hot wire current, wire delivery speed, welding speed, walking distance/rotation angle, and control welding travel, automatic welding;

- Precisely set the distance between tungsten electrode and workpiece, tungsten electrode touches the workpiece after the promotion to the set value, the arc ingress is high frequency arcing;

- With a constant temperature water cooling system to ensure long-term continuous operation of the system;

- Improve the fault detection system and directly display the fault and troubleshooting guidance methods;

- Scientific modular design, proven control system for easy maintenance and maintenance;

- High real-time, high reliability, high precision, openness to meet almost all workpiece welding needs;

- Automatic control system with manual adjustment, automatic welding two ways;

- The system has a breakpoint memory function that automatically returns to the breakpoint;

- The automatic control system can realize three kinds of welding methods, main hole welding, side hole welding and round flat surface welding;

- With offline programming, offline printing function. (This feature is not included in this Agreement)

XHL-HCS Container Integrated Horizontal cladding station which is designed for heavy and complex shaped products for oil & gas, chemical, valve manufacturing, pressure vessels and other industries, the welding torch is designed to meet the requirements of a wide range of different shape products. This machine can be used for precision welding of corrosion-resistant materials and wear-resistant materials.

This model is compact design, space saving, powerful. Equipped with the basic function of horizontal inner wall surfacing cladding, the equipment has the function of feeding, and can transport the steel pipe to the clamping part of the positioner. Other functions determine the welding program index of the whole machine according to the business contract option.

The valve inner wall automatic cladding equipment adopts non-melting pulsed TIG hot wire fill cladding technology. Suitable for automatic surfacing welding of carbon steel wire, stainless steel wire, nickel-based alloy wire, wear-resistant wire, etc.

Stability, efficiency, innovation and integrity are the principles that FITco adheres to. Our design principle is to ensure the stability of the equipment first, so we choose international first-class controllers, electrical components, welding power sources. Our equipment adopts the most advanced and most stable digital communication protocol Ethernet/IP, which ensures the stability and timely of the equipment internal communication, also reserves the most reliable interface and the most convenient communication protocol for users to achieve factory-level digitalization in the future. Ethernet/IP can be easily realized in the TCP/IP communication protocol information and data inter working, laying a solid foundation for the realization of real industry 4.0 and smart factory!

Fitco has grown and developed from a cladding and prefabricated products manufacturing plant, from the equipment maintenance department of the product manufacturing plant to a professional cladding and prefabrication equipment manufacturer, so we are more familiar with the problems that users may encounter, in addition to the equipment itself, our familiarity with the welding process is much higher than our competitors。

Key Parameters:

1 |

Type of Power Source |

DC Type Inverter |

2 |

Welding Current Duty Cycle(40℃) |

5~450A 450A 80%; 420A 100% |

3 |

Hot Wire Current Duty Cycle(40℃) |

5~200A 200A 60%; 100A 100% |

4 |

Deposit Rate |

1.3kg/H |

5 |

Occupied Area |

18m2 |

6 |

Open Circuit Voltage |

80V |

7 |

Input Voltage |

3×400V(-25%+20%) 50/60Hz |

8 |

Input Power |

35KVA |

9 |

Power Source Cooling |

Air Cooling |

10 |

Display |

5.7”Chinese/English interface |

11 |

Data Setting Method |

Touch panel setting |

12 |

Display |

Touch screen /Control panel real-time display |

13 |

Fault Detect |

Work piece short circuit,over temperature protection,over current protection,over voltage protection,water shortage protection, lack of gas protection, power error, arc failure, servo error. |

14 |

Torch Cooling |

External Constant Temperature Circulating Water Cooling |

15 |

Cladding Capacity |

Dia: Φ50-Φ850mm Max. height of horizontal cladding ≦500mm Weight Capacity: 5T |

16 |

AVC Accuracy |

±0.2V |

17 |

Recommend Peak Current |

150~280A |

18 |

Recommend Base Current |

100~200A |

19 |

Recommend Voltage |

8~16V |

20 |

Tungsten Dia. |

3.2mm,4.0mm optional |

21 |

Wire Dia. |

1.2/1.0mm, 1.0/1.2mm optional |

22 |

Recommend Single Layer Thickness |

1~3mm |

23 |

Recommend gas flow rate |

12~20L/min |

24 |

Arc-starting |

HF/Contact |

25 |

Manufacturing standards |

GB15579 The newest version |

26 |

Insulation safety rating / standard |

H/IP23 |

Welding Power Supply System

Control System:

i -CLAD 100 is developed by FITco using the world's most advanced technology for the design, manufacture of welding control system, the system uses the United States Rockwell AB PLC system control, combining FITco's development, manufacturing experience in one, with advanced, digital, easy to operate, intelligent, universal, reliability and so on. The operating system centrally sets, stores, controls distributed synchronization and has good scalability of the functional parameters in the welding.

System Feathers:

When adjusted manually, each moving shaft can be adjusted separately, and the welding starting point can be set.;

When welding automatically, according to the set welding process parameters, according to a certain mathematical model smoothly;

Optional program function configuration (the following functions are only applicable when included in the business contract) : Ø

After-sales Service

After the expiration of the warranty, Supplier will carry out life-long maintenance of their products and provide a wide range of preferentical technical support in life.

During the quality assurance period, when the equipment failure in the process of use of the equipment is not resolved, Party B in the notice within 8 hours to respond, such as Customer still cannot troubleshoot, Supplier within 1 week to send maintenance engineers.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LT

LT UK

UK SQ

SQ HU

HU TH

TH TR

TR FA

FA AF

AF CY

CY MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY