Compact Vertical Cladding Station

Compact vertical cladding station is space-saving and powerful.

Roller-guided wire feeding system offers perfect wire feeding. Servo drive with precision gearing offers maximum positioning accuracy.

Main power source and hot wire source are produced by EWM Germany.

The rotatory table diameter is 1400mm, loading capacity can be up to 10 ton.

- Overview

- Recommended Products

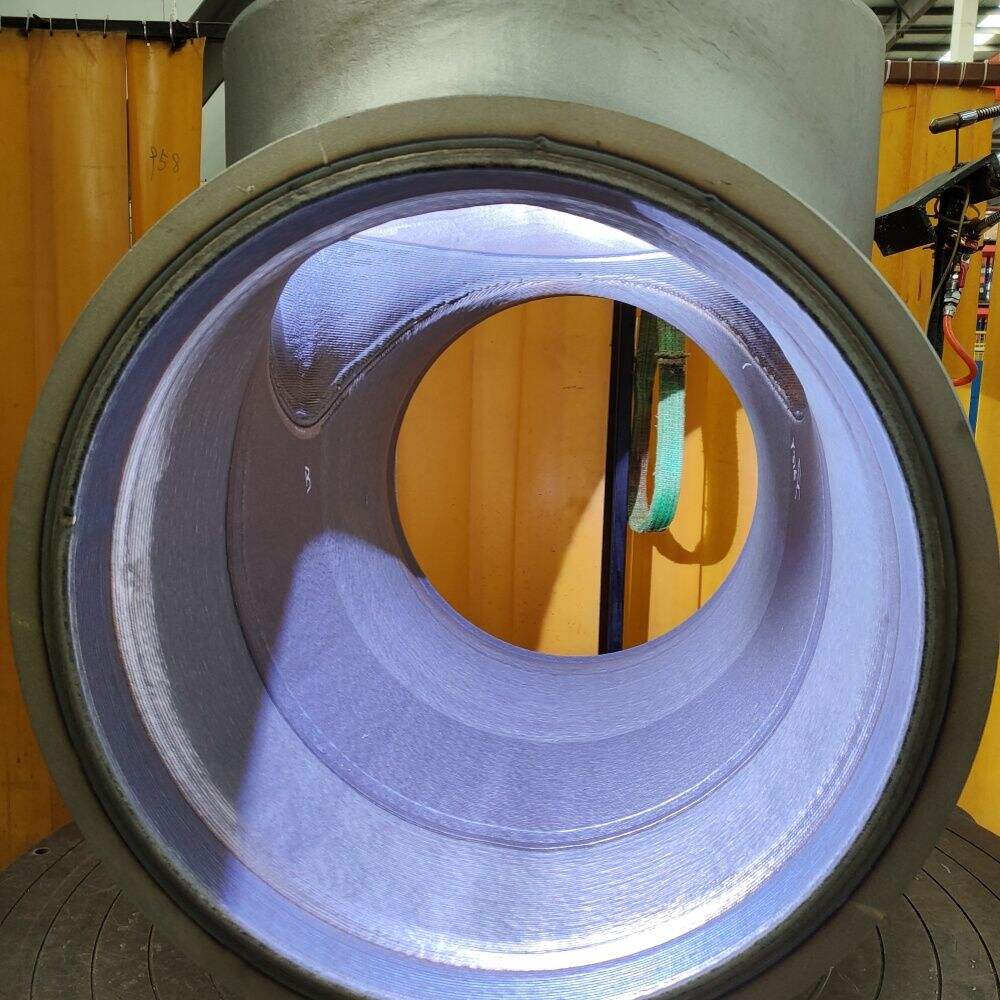

The compact type vertical cladding station is designed for oil and gas, chemical, valve manufacturing, pressure vessels and other industries. Requirements of products with a variety of shapes can be met. This model can be used for precision welding of corrosion-resistant and wear-resistant materials.

With compact design, this model is space-saving and powerful. Configured with the basic functions of internal and external surface together with flat surface welding, this mode also boasts optional functions such as two holes 90-degree crossing intersection surface cladding, multi-bore intersection surface automatic welding, workpiece pre-heat system, workpiece cooling system, etc.

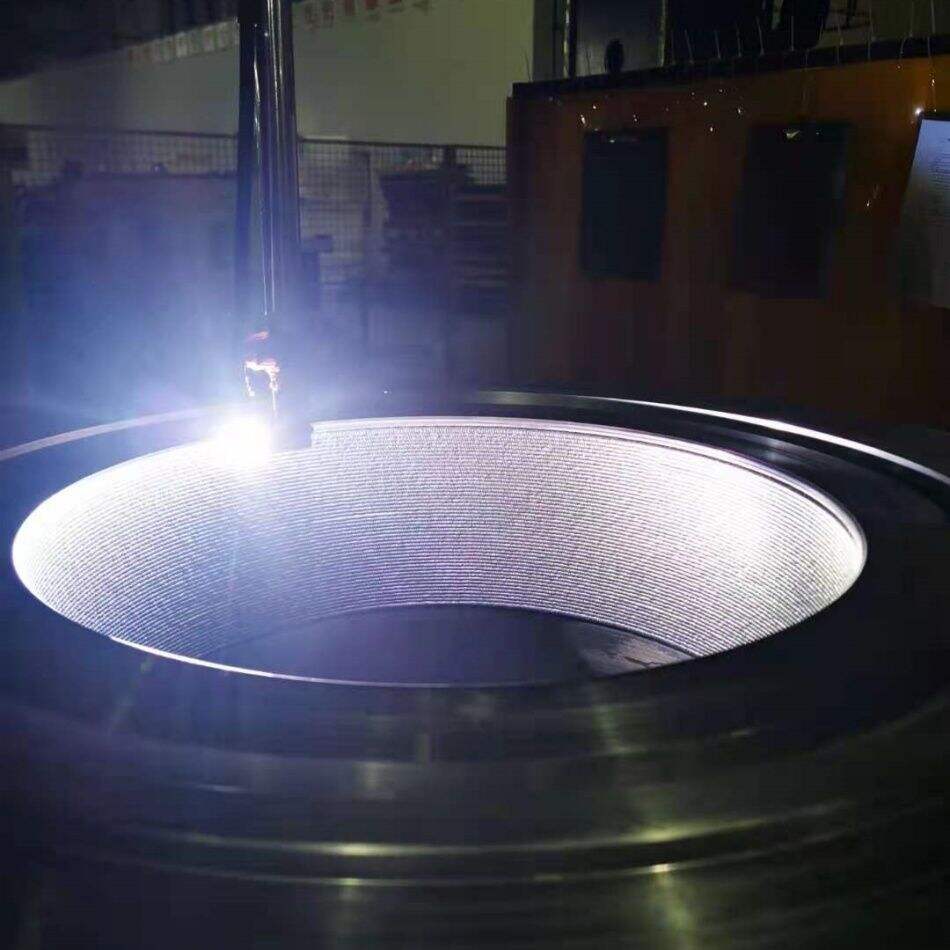

The cladding station is using TIG hot wire welding process. Suitable for automatic welding of carbon steel wire, stainless steel wire, nickel-based alloy wire, wear-resistant welding wire and other materials.

Equipment Key Components:

i. Mechanical system:

Two-dimensional CNC motion guide

2.5mX2.8m (horizontal*vertical) cross operator (effective travel 1.6mX1.9m)

Welding turntable

Automatic water-cooled torch, and other components.

ii. Power Source system:

EWM EtherNet/IP TETRIX 452 DC Pulse TIG power source

EWM TETRIX 200 SMART HOT WIRE

iii. Automatic control system: i-CLAD 200:

Main control cabinet, hand held controller, ICON/MOONS servo control system, CompactLogix 5370 controller.

iv. Water cooling system:

Constant temperature water cooling system for long-time operation.

|

|

|

Product parameter table:

1 |

Type of Power Source |

DC Type Inverter |

2 |

Weld Current Duty Cycle (40℃) |

5~450A 450A 80%; 420A 100% |

3 |

Hot wire current Duty Cycle (40℃) |

5~200A 200A 60%; 100A 100% |

4 |

Cladding Capacity |

1.3kg/H |

5 |

Occupied Area |

12㎡ |

6 |

Open circuit voltage |

80V |

7 |

Input Voltage |

3×400V (-25%+20%) 50/60Hz |

8 |

Input Power |

35KVA |

9 |

Inverter Cooling |

Air cooling |

10 |

Displayer |

5.7”screen Chinese/English displayer Real-time parameter display |

11 |

Data setting method |

Touch panel setting |

12 |

Fault Detect |

Work piece short circuit, over temperature protection, over current protection, over voltage protection, water shortage protection, lack of gas protection, power error, arc failure, servo error. |

13 |

Torch Cooling |

External Constant Temperature Circulating Water Cooling |

14 |

Overlay Processing |

Dia.: φ38 (after cladding) – φ1200mm Max height for vertical overlay: ≤1500mm Loading bearing 5 tons Dia. of turntable 1200mm. |

15 |

AVC Accuracy |

±0.2V |

16 |

Recommend Peak Current |

150~280A |

17 |

Recommend Base Current |

100~200A |

18 |

Recommend Voltage |

8~16V |

19 |

Tungsten Dia. |

3.2mm (4.0mm Optional) |

20 |

Wire Dia. |

1.0/1.2mm (1.6mm Optional) |

21 |

Single Layer Thickness |

1-3mm |

22 |

Recommend gas flow rate |

12~20L/min |

23 |

Arc Starting |

HF/Contact |

24 |

Manufacture Standard |

Latest Version of GB15579 |

25 |

Insulation Safety Level /Standard |

H/IP70 |

|

26 |

Equipment Dimension |

3700mmx1700mmx4000mm |

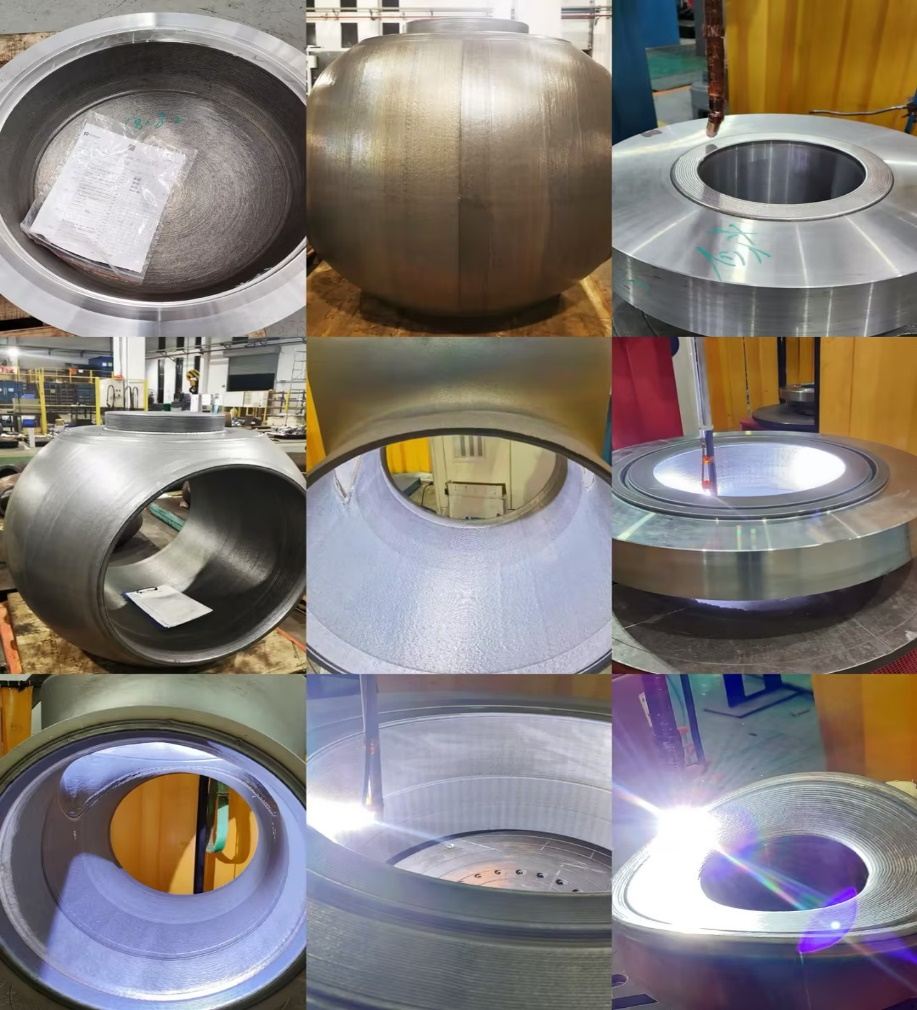

Application Products:

Pipe rings, Fittings, Flanges, LR bends, Valve Bodies, Valve Balls, Risers, Well head block tree valves, Pressure Vessel Components, Nozzle, Dished ends, etc.

Designed to address the core pain points of industrial welding, our Compact Vertical Cladding Station integrates precision, flexibility, and user-friendliness. It breaks through the limitations of traditional cladding equipment and provides a professional solution for high-quality cladding operations in diverse manufacturing scenarios.

1.Compact Design, Maximum Space Utilization

Pain Point Solved:Traditional cladding workstations are often bulky and heavy, requiring extensive workshop space and making it difficult to adapt to small factories, multi-station switching, or narrow operation areas. This leads to low equipment utilization and high deployment costs.

Core Advantage:Centered on the "compact" concept, the station significantly reduces floor space and overall weight while retaining full cladding functionality. It can be flexibly integrated into existing production lines, narrow work zones, or temporary workstations—no large-scale workshop renovation required.

Competitive Edge:Unlike the "large and all-inclusive" traditional cladding equipment on the market, we focus on "small but refined" scenario adaptability. It is especially tailored for small and medium-sized manufacturing enterprises, multi-variety small-batch production, or workshops with limited space, lowering the threshold for equipment deployment and improving space utilization.

2.Vertical Structure + Precision Control, Stable Cladding Quality

Pain Point Solved:Cladding operations demand high uniformity of weld thickness and strong bonding strength of the cladding layer. Traditional horizontal equipment or manual-assisted operations are prone to workpiece positioning deviations and fluctuations in welding parameters, resulting in weld defects such as slag inclusion, porosity, and uneven thickness, leading to high rework rates.

Core Advantage:The "vertical" structure design, combined with a high-precision mechanical positioning system, enables stable clamping and uniform feeding of workpieces in the vertical direction. Equipped with digital welding parameter control (e.g., closed-loop control of current, voltage, and wire feeding speed), it ensures tight bonding of the cladding layer with small thickness tolerance, significantly reducing defect rates.

Competitive Edge:Focused on the specialized optimization of "vertical cladding," it reduces the risk of workpiece deformation compared to horizontal equipment and enhances parameter adaptability for cladding scenarios compared to general-purpose welding machines. It is particularly suitable for internal/external wall cladding of shaft and cylinder workpieces, emphasizing "high precision for specialized scenarios" rather than "broad but shallow" general-purpose welding.

3.Integrated Design, Simplified Operation & Maintenance

Pain Point Solved:Traditional cladding equipment mostly adopts modular splicing, requiring separate matching of welding power sources, wire feeders, cooling systems, etc. Installation and commissioning are cumbersome, with poor compatibility between components leading to high later maintenance costs. Meanwhile, the high operational threshold requires professional technical personnel.

Core Advantage:Integrating the welding power source, wire feeding mechanism, cooling system, and vertical tooling in one unit, it is "ready to use" without complex splicing. Equipped with a user-friendly operation interface (e.g., touch screen, preset cladding parameter library), it simplifies parameter setting and reduces the skill requirements for operators. All components are factory-matched, featuring low failure rates and standardized maintenance processes.

Competitive Edge:Different from "split-type" equipment on the market, it highlights "integration + ease of operation." Especially addressing the pain points of small and medium-sized enterprises—such as shortage of technical personnel and limited maintenance capabilities—it lowers the equipment usage threshold and improves operational efficiency.

4.High Adaptability + Energy-Saving Design, Balance Flexibility & Economy

Pain Point Solved:In multi-variety production scenarios, cladding workpieces vary greatly in specifications (diameter, length). Traditional equipment has a narrow adaptation range, requiring frequent tooling replacement. Meanwhile, welding equipment consumes high energy, resulting in significant long-term usage costs.

Core Advantage:The vertical tooling supports quick model changeover for workpieces of multiple specifications (e.g., shafts and cylinders of different diameters) without the need for additional customized tooling. Adopting an energy-saving welding power source and intelligent energy consumption control technology, it reduces energy consumption by 15%-20% compared to traditional equipment, significantly lowering electricity costs during long-term use.

Competitive Edge:Balancing "multi-variety adaptability" and "energy-saving cost reduction," it differs from specialized equipment for single-specification adaptation and high-energy-consuming traditional models. It is particularly suitable for multi-variety small-batch production enterprises, achieving a balance between production flexibility and operational economy.

Fit-Weld Commitment:Our Compact Vertical Cladding Station is engineered to solve real-world welding challenges. With a focus on reliability, efficiency, and user-centric design, it helps enterprises improve production quality, reduce costs, and enhance core competitiveness in the fierce market competition. Contact us today to learn more about how this station can tailor to your specific welding needs.

5.After-Sales Support

We take full responsibility for providing professional after-sales technical services and genuine spare parts supply, ensuring your equipment operates smoothly throughout its lifecycle.

Product Warranty Commitment

We provide a 12-month quality warranty for all equipment, starting from the date of final acceptance and signature. This warranty covers equipment quality issues under normal usage conditions, with the exception of consumable parts and damages caused by human factors.

(i)Within the warranty period: If the equipment malfunctions due to inherent quality defects, we will provide free maintenance and repair services. For failures caused by improper operation, our technicians will respond promptly to resolve the issue, and reasonable service costs will be borne by the customer.

(ii)Important Note: The use of non-genuine spare parts or substitutes will result in the automatic termination of your warranty rights.

Lifelong Maintenance & Support

Our commitment doesn't end with the warranty. After the 12-month warranty expires, we continue to offer lifelong maintenance services for all our products. You can also enjoy preferential technical support for life, ensuring long-term value from your investment.

During the warranty period, we prioritize your production efficiency with a rapid response system:

(ii)Upon receiving your equipment fault notification, we will provide a response within 8 hours to guide troubleshooting.

(ii)If the issue cannot be resolved remotely, we will dispatch professional maintenance engineers to your site within 1 week to address the problem.

With our comprehensive after-sales support, you can focus on your core operations while we take care of your equipment needs. For any after-sales inquiries, feel free to contact our dedicated service team anytime

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LT

LT UK

UK SQ

SQ HU

HU TH

TH TR

TR FA

FA AF

AF CY

CY MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY