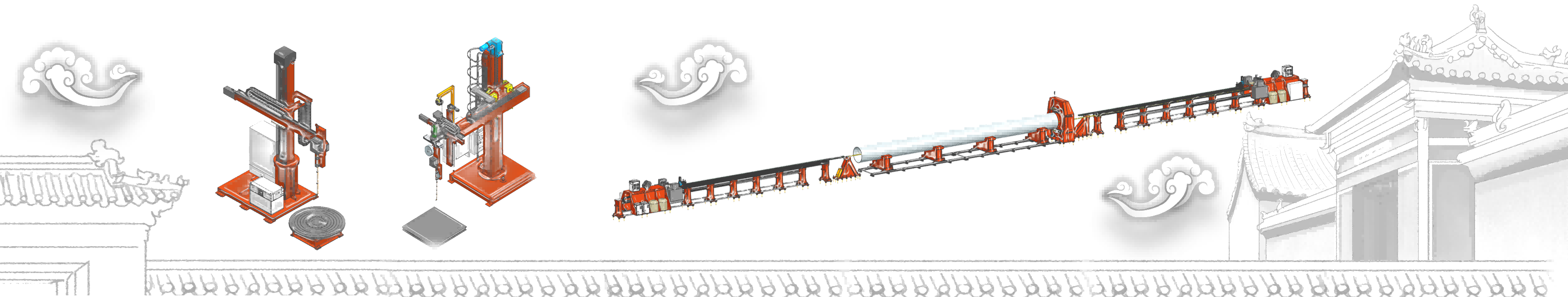

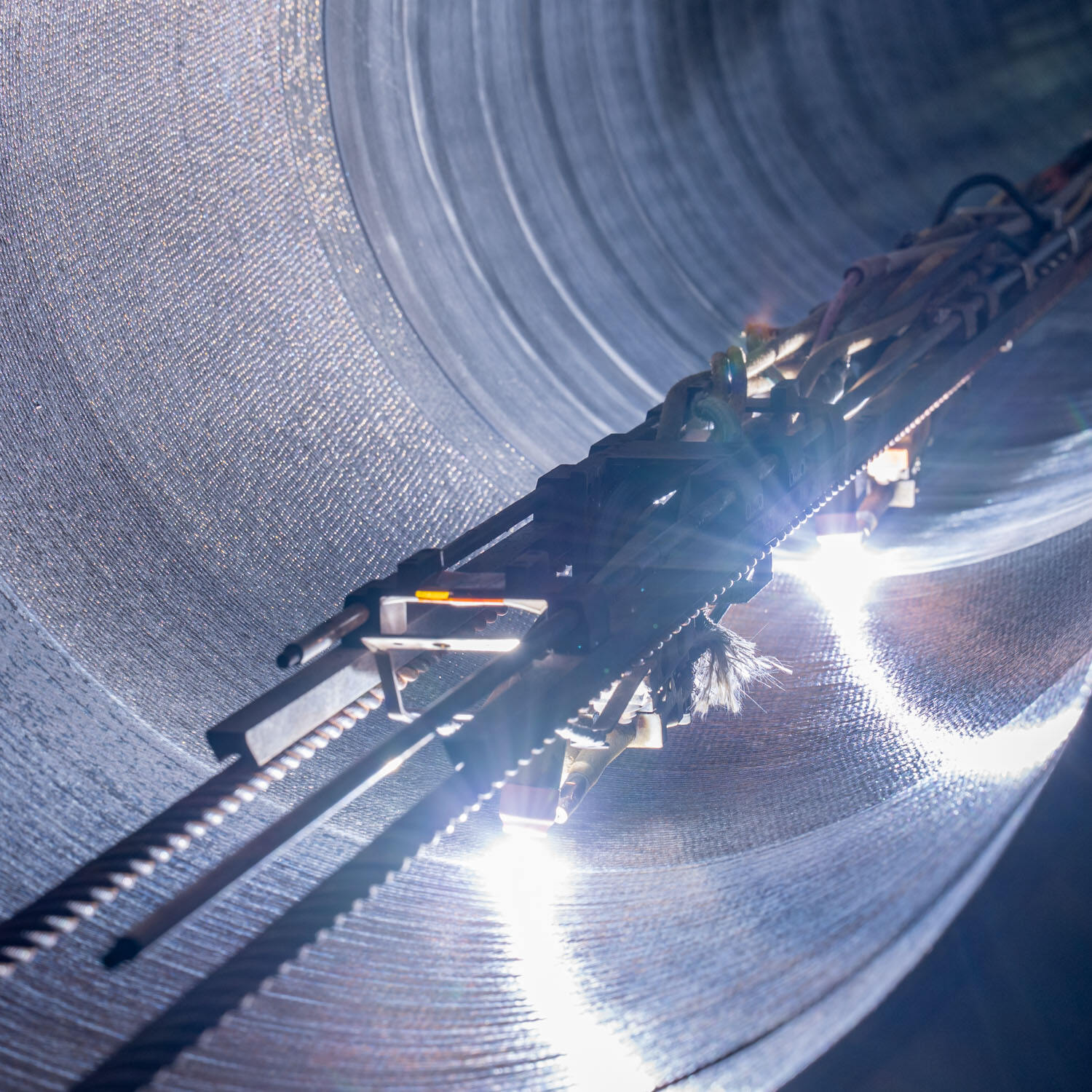

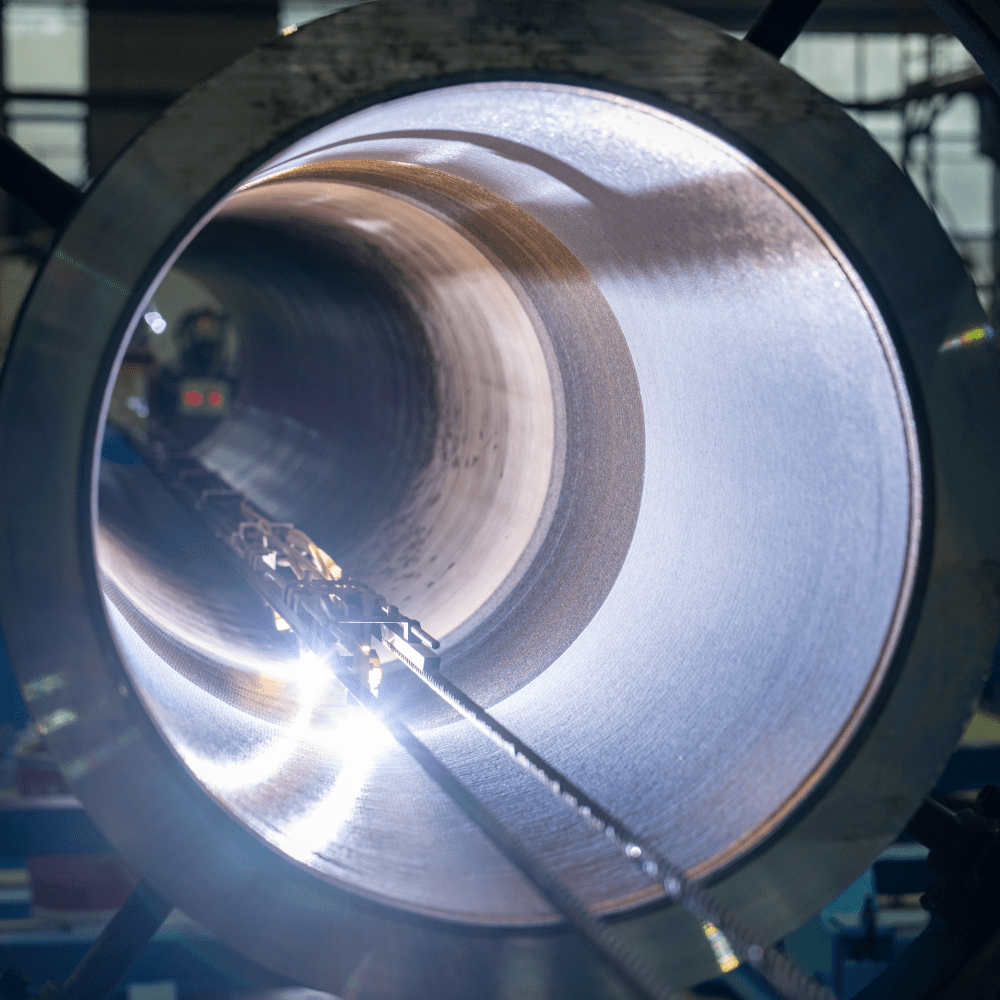

Oil & Gas Pipe Cladding Overlay TIG Welding Machine

With the twin torch twin wire design, the deposit rate can up to 5.0kg/hour.

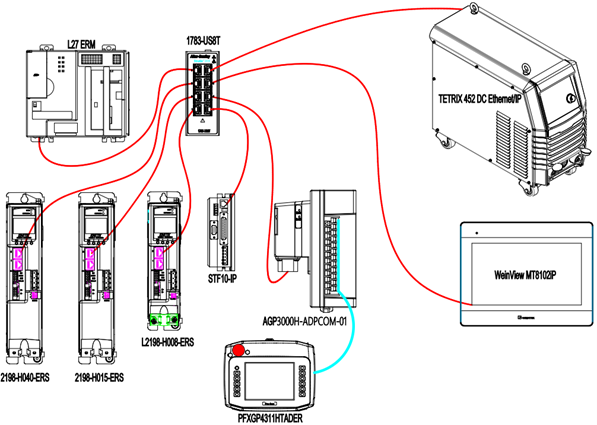

With the EWM TETRIX 452 DC pulse arc welding power supply and the TETRIX 200 HOT WIRE thermal wire power supply.The welding performance is very excellent.

Rockwell AB's latest generation PLC and servo system, EtherNet/IP digital communication is used to control and monitor a wide range of input, output and sampling signals in high resolution.

- Overview

- Recommended Products

- Touch & retract

- Online adjust

- AVC-Arc Voltage Control

- Actual value visualization

- Remote support

- Bore-to-bore

- Data Logge

- The welding power supply is powered by TETRIX 452 DC-type DC pulse arc welding power supply produced by EWM AG, Germany.The welding maneuvering characteristics are good, the continuous operation is stable and reliable, and its pulse function meets the process requirements of welding.

- The TETRIX 200 HOT WIRE thermal wire power supply from EWM is used.

- Working temperature: -40ºC~+55ºC

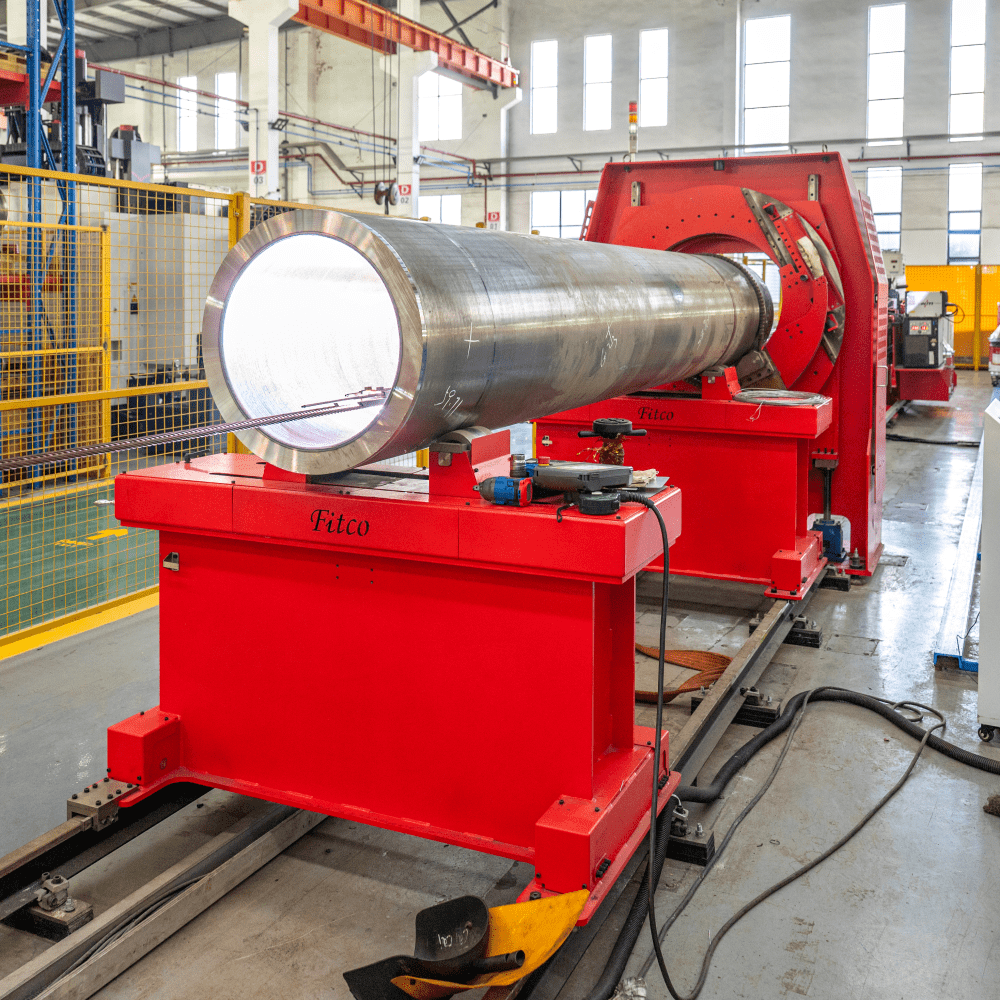

FITco is honored to provide model XHL-PCS cladding station which is designed for pipes and vessels for oil & gas, chemical, valve manufacturing, pressure vessels and other industries.

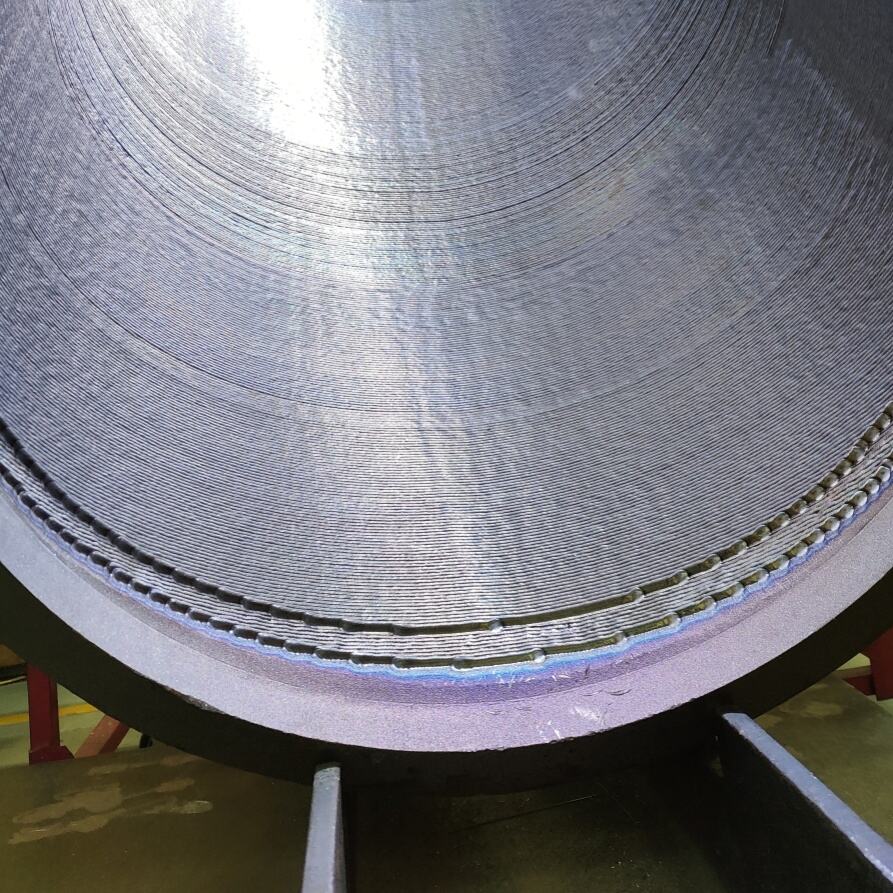

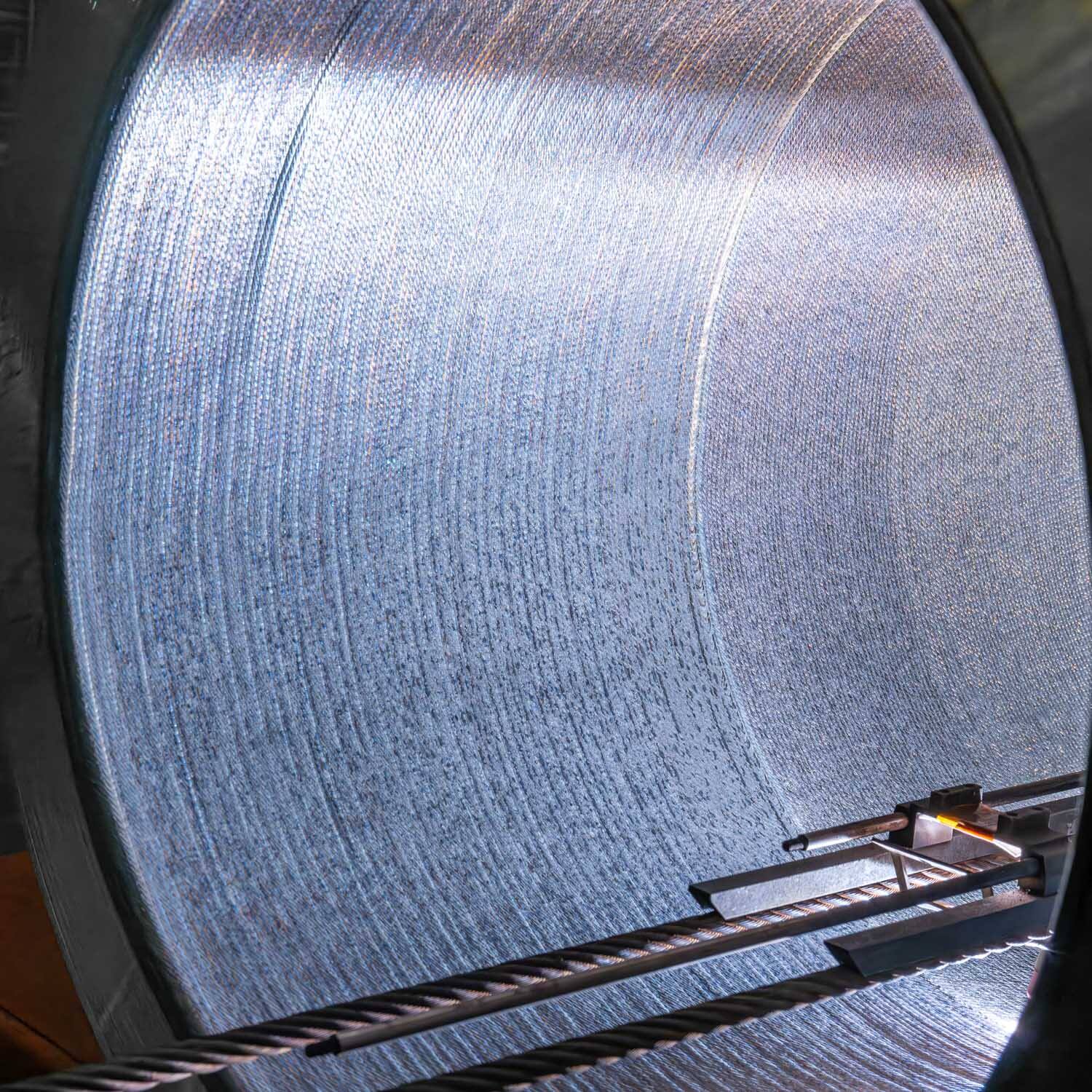

The equipment is mainly used for less than 12.5m tube inner wall anti-corrosion welding, welding pipe is driven by end hollow chuck rotation, welding torch by wire rope pull and guide equipment positioning and complete welding into the channel.

- Workpiece weight: up to 10Ton

- Tube material: API 5L Gr.B, X52, X60, X65, stainless steel, CrMo steel, etc.

- Bevel form: inner wall welding without sloping

- Bevel group pair: None;

- Welding position: 1G position welding (weld gun not moving, workpiece rotation)

- Welding method: hot wire TIG

- Warm-up requirements: According to the welding process, the system is not configured to warm up the system.

- Welding layer inspection requirements: 100% UT layering/100% PT

- Typical workpieces: hot-rolled steel pipes, seamless steel pipes, forging tubes, etc.

Technical Parameters:

1 |

Type of Power Source |

DC Type Inverter |

2 |

Weld Current Duty Cycle(40℃) |

5~450A 450A 80%; 420A 100% |

3 |

Hot wire current Duty Cycle(40℃) |

5~200A 200A 25%; 150A 60%; 140A 100%. |

4 |

Open circuit voltage |

80V |

5 |

Input Voltage |

3×400V(-25%+20%) 50/60Hz |

6 |

Input Power |

60 KVA |

7 |

Inverter Cooling |

Air cooling |

8 |

Display |

5.7” Touch Panel handheld interface / 12” Touch Panel on Control Cabinet |

9 |

Data setting method |

Touch panel setting |

10 |

Fault detect |

Work piece short circuit,over temperature protection,over current protection,over voltage protection,water shortage protection, lack of gas protection, power error, arc failure. |

11 |

Torch |

Twin Torches with individual External Constant Temperature Circulating Water Cooling with chiller |

12 |

Cooling water volume |

6L |

13 |

Manufacture Standard |

GB15579-2004 |

14 |

Insulation Safety Level /Standard |

H/IP23 |

15 |

Cladding capacity |

OD : Φ168 ~ Φ850mm / 6 to 32 Inch ID minimum 140 after clad. Length: Max 6500mm to 12500mm as per Purchase order |

16 |

Deposit Rate(2 Torch) |

Max 4 Kg/hour for long term stable operation. Capacity up to 6kg/hour (according to the condition of pipe grinding, straightness and diameter) |

17 |

Overlay Travel Speed |

Up to 1200mm/Min |

18 |

Wire feeding Speed |

Up to 5M/Min |

19 |

AVC Accuracy |

±0.3V |

20 |

Recommend Peak Current |

150~280A |

21 |

Recommend Base Current |

100~200A |

22 |

Recommend Voltage |

8~16V |

23 |

Tungsten Dia. |

3.2/4.0mm |

24 |

Wire Dia. & Spool Size |

1.2/1.6mm 15kgs BS 300 Spools(Φ300xW104xC53mm) or 250 kgs barrel welding wire |

25 |

Single Layer Thickness |

1~3mm |

26 |

Recommend gas flow rate |

12~20L/min |

27 |

Arc-starting |

HF/Contact |

|

|

|

|

Equipment Instructions

The equipment is mainly used for long tube inner wall welding, the base tube is driven and rotated by the hollow chuck welding swing mechanism, the welding gun is positioned by the wire rope pull and the guide equipment and completed the welding into the passage.

The equipment consists of welding power supply, welding head, head drive guidance system, welding swing mechanism, roller frame, electrical control system and water-cooling system.

|

|

SYSTEM CONTROLLER AND REMOTE CONTROLLER

WO-ACS SERIES SOFTWARE base on

Welding Power Source System:

Cabinet Air Conditioning is optional

Cabinet air conditioners are used in areas with high emperature .

After-Sales Support

We take full responsibility for providing professional after-sales technical services and genuine spare parts supply, ensuring your equipment operates smoothly throughout its lifecycle.

Product Warranty Commitment

We provide a 12-month quality warranty for all equipment, starting from the date of final acceptance and signature. This warranty covers equipment quality issues under normal usage conditions, with the exception of consumable parts and damages caused by human factors.

(i)Within the warranty period: If the equipment malfunctions due to inherent quality defects, we will provide free maintenance and repair services. For failures caused by improper operation, our technicians will respond promptly to resolve the issue, and reasonable service costs will be borne by the customer.

(ii)Important Note: The use of non-genuine spare parts or substitutes will result in the automatic termination of your warranty rights.

Lifelong Maintenance & Support

Our commitment doesn't end with the warranty. After the 12-month warranty expires, we continue to offer lifelong maintenance services for all our products. You can also enjoy preferential technical support for life, ensuring long-term value from your investment.

During the warranty period, we prioritize your production efficiency with a rapid response system:

(ii)Upon receiving your equipment fault notification, we will provide a response within 8 hours to guide troubleshooting.

(ii)If the issue cannot be resolved remotely, we will dispatch professional maintenance engineers to your site within 1 week to address the problem.

With our comprehensive after-sales support, you can focus on your core operations while we take care of your equipment needs. For any after-sales inquiries, feel free to contact our dedicated service team anytime

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LT

LT UK

UK SQ

SQ HU

HU TH

TH TR

TR FA

FA AF

AF CY

CY MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY