Endless Torch Rotate Cladding Station

Thanks to the intelligent iClad 300 system control, components with multiple boreholes and different borehole angles can be welded as standard.

Job sizes for ETR range from 38 to 3000mm in diameter and less than 3000mm in height. (ф38~ф3000mm, height up to≤3000mm)

All components are from well-known brands, such as EWM power source, Rockwell AB PLC, HIWIN, Proface remote control, Schneider and others.

- Overview

- Recommended Products

- GB 15579.1to10 Arc Welding Equipment

- JB/T 6965-1993 Welding Operator's Frame

- GB/T 1184-1996 《Shape Given Position Tolerance》

- GB/T 10089-1988 Garden Cochlear Wheel, Worm Accuracy

- GB/T 25295-2010 Guidelines for the Safety Design of Electrical Equipment

- GB6988-86 Electrical Mapping

- Valve industry: Overlay welding of valve bodies, valve cores, valve seats (including ball valves, gate valves, globe valves, check valves, etc.)

- Pipe fitting industry: Welding of elbows, tees, reducers, flanges, pipe ends and other components

- Pressure vessel industry: Overlay welding of vessel heads, cylinder bodies, manholes and other key parts

- Oil & gas industry: Welding of downhole tools, wellheads, pipelines and other corrosion-prone components

- Other fields: Nuclear power equipment, marine engineering components, chemical reaction kettle linings and other high-demand welding scenarios

-

Pain Point 1: Low welding precision, easy to have defects such as uneven welds and excessive dilution rate

Solution: Equipped with infinite rotation welding head and arc voltage automatic tracking function (±0.2V), which ensures stable welding trajectory and uniform weld formation. The advanced pulse TIG hot wire filling process controls the dilution rate below 5%, avoiding defects such as porosity, cracks and uneven thickness, and ensuring the consistency of welding quality. -

Pain Point 2: Complex workpieces are difficult to position, time-consuming and labor-intensive for manual alignment

Solution: Adopt Fitco i-CLAD 300 intelligent control system with automatic centering function. It can quickly and accurately locate the welding position without complicated manual adjustment, greatly reducing the time for workpiece alignment and debugging, improving work efficiency and reducing labor costs. -

Pain Point 3: Large and heavy workpieces are inconvenient to process, and the equipment occupies a large space

Solution: The product adopts a compact design, which saves workshop space and is easy to install and debug. It supports the welding of large-diameter workpieces (Φ38~Φ3000mm for E model, Φ50~Φ2500mm for F model) and can bear heavy-duty components, effectively solving the problem of difficult processing of large and heavy workpieces. -

Pain Point 4: Poor adaptability to multi-shape workpieces, unable to meet diversified welding needs

Solution: The infinite rotation welding head can flexibly adapt to the welding of inner/outer walls, flat surfaces, curved surfaces and other multi-shape workpieces. Optional 90° intersecting holes welding (for pipe fittings and tees) and sphere hole avoidance (for pressure vessel heads) functions, fully meeting the diversified welding needs of different industries. -

Pain Point 5: Low welding efficiency, high rework rate, and increased production costs

Solution: The pulse TIG hot wire filling process has high welding efficiency, with a single-layer weld thickness of 1~3mm. The product meets ASTM E165 and ASTM V standards, and the first-pass yield is as high as 98%, which greatly reduces the rework rate and saves material and time costs for customers. -

Pain Point 6: Unstable equipment operation under harsh working conditions, frequent failures

Solution: The equipment is equipped with high-quality core components (Rockwell PLC, EWM/TETRIX power supply, Pro-face HMI) and a forced water cooling system. It has complete fault protection functions and can operate stably for 24 hours under harsh conditions such as high temperature, low temperature and heavy dust, reducing the risk of equipment failure and ensuring continuous production. - Intelligent control system, automatic centering, saving manual alignment time and improving efficiency

- Compact structure, space-saving, suitable for various workshop layouts

- Infinite rotation welding head, high precision, strong adaptability to multi-shape workpieces

- Advanced pulse TIG hot wire process, high welding quality and efficiency, low dilution rate

- High-quality configuration, stable operation, long service life, low maintenance cost

- Complies with international standards, high first-pass yield, and reliable product performance

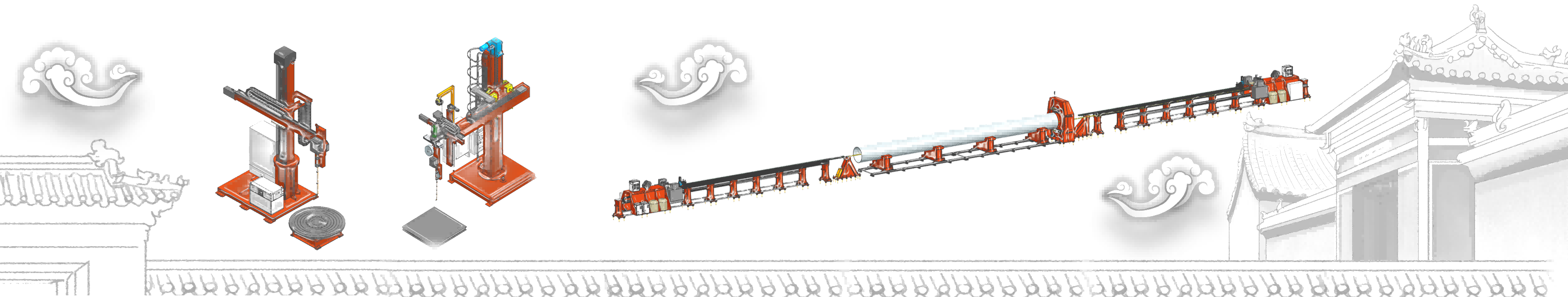

FITco is honored to provide model XHL-ETR cladding station which is designed for heavy and complex shaped products for oil & gas, chemical, valve manufacturing, pressure vessels and other industries, the welding torch is designed as endless rotation which can meet the requirements of a wide range of different shape products.

Fitco can specially design and produce the tig welding equipments according to clients' requirements.

Heavy and complex component welding is always a huge challenge. This is where the advantages of the FITco ETR system come into play, thanks to intelligent Fitco i-CLAD 300 control system, this model features multiple holes and standard welding of components of different angle and sizes.

The automatic alignment function significantly reduces the time required to manually find centers for traditional heavy components.

With compact design, this model is space-saving and powerful. Configured with the basic functions of internal and external surface together with flat surface welding, this mode also boasts optional functions such as two holes 90-degree crossing intersection surface cladding, multi-bore intersection surface automatic welding, workpiece pre-heat system, workpiece cooling system, etc.

Equipment Key Components:

Mechanical System: Heavy-duty cross operator, 3D CNC motion control column & Booms, workpiece placement platform, automatic water-cooled endless rotating welding torch, Optional Servo Control Rotating Table

Automatic welding control system: welding motion control system, welding power supply, water cooling system and cabinet air conditioning.

Product parameter table:

1 |

Type of Power Source |

DC Type Inverter |

2 |

Weld Current Duty Cycle(40℃) |

5~450A 450A 80%; 420A 100% |

3 |

Hot wire current Duty Cycle(40℃) |

5~200A 200A 60%; 100A 100% |

4 |

Cladding Capacity |

1.3kg/H |

5 |

Occupied Area |

20m2 |

6 |

Open circuit voltage |

80V |

7 |

Input Voltage |

3×400V(-25%+20%) 50/60Hz |

8 |

Input Power |

35KVA |

9 |

Inverter Cooling |

Air cooling |

10 |

Displayer |

5.7” screen Chinese/English displayer |

11 |

Data setting method |

Touch panel setting |

12 |

Display |

Touch screen/Panel/Bilingual real-time parameter display |

13 |

Fault detect |

Work piece short circuit,over temperature protection,over current protection,over voltage protection,water shortage protection, lack of gas protection, power error, arc failure,servo error. |

14 |

Torch Cooling |

External Constant Temperature Circulating Water Cooling |

15 |

Cooling water volume |

15L |

16 |

Cladding capacity |

Size: ф38~ф3000mm; Height up to ≤2500mm |

17 |

AVC Accuracy |

±0.2V |

18 |

Recommend Peak Current |

150~280A |

19 |

Recommend Base Current |

100~200A |

20 |

Recommend Voltage |

8~16V |

21 |

Tungsten Dia. |

3.2mm 4.0mm (Optional) |

22 |

Wire Dia. |

1.2/1.6mm 1.0mm (Optional) |

23 |

Single Layer Thickness |

1~3mm |

24 |

Recommend gas flow rate |

12~20L/min |

25 |

Arc-starting |

HF/Contact |

26 |

Manufacturing standards |

|

27 |

Insulation safety rating / standard |

H/IP23 |

Core Application Scope

The product covers a wide range of welding scenarios for key components in industrial production, including but not limited to:

Pain Points & Product Solutions

We deeply understand the difficulties and troubles that customers face in the welding process. The FIT-ETR series is developed to solve these core problems one by one:

Core Advantages

After-Sales Support

We take full responsibility for providing professional after-sales technical services and genuine spare parts supply, ensuring your equipment operates smoothly throughout its lifecycle.

Product Warranty Commitment

We provide a 12-month quality warranty for all equipment, starting from the date of final acceptance and signature. This warranty covers equipment quality issues under normal usage conditions, with the exception of consumable parts and damages caused by human factors.

(i)Within the warranty period: If the equipment malfunctions due to inherent quality defects, we will provide free maintenance and repair services. For failures caused by improper operation, our technicians will respond promptly to resolve the issue, and reasonable service costs will be borne by the customer.

(ii)Important Note: The use of non-genuine spare parts or substitutes will result in the automatic termination of your warranty rights.

Lifelong Maintenance & Support

Our commitment doesn't end with the warranty. After the 12-month warranty expires, we continue to offer lifelong maintenance services for all our products. You can also enjoy preferential technical support for life, ensuring long-term value from your investment.

During the warranty period, we prioritize your production efficiency with a rapid response system:

(ii)Upon receiving your equipment fault notification, we will provide a response within 8 hours to guide troubleshooting.

(ii)If the issue cannot be resolved remotely, we will dispatch professional maintenance engineers to your site within 1 week to address the problem.

With our comprehensive after-sales support, you can focus on your core operations while we take care of your equipment needs. For any after-sales inquiries, feel free to contact our dedicated service team anytime

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LT

LT UK

UK SQ

SQ HU

HU TH

TH TR

TR FA

FA AF

AF CY

CY MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY