inverter igbt welder

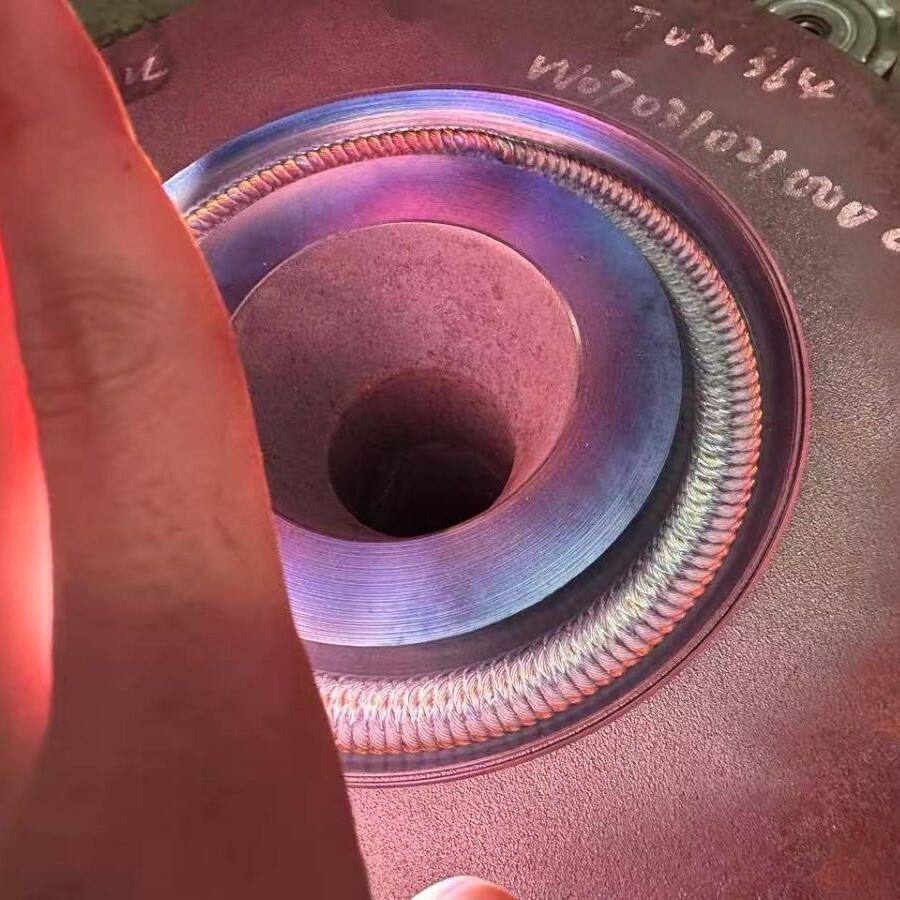

The inverter IGBT welder represents a significant advancement in welding technology, combining sophisticated electronic control with efficient power management. This modern welding system utilizes Insulated Gate Bipolar Transistor (IGBT) technology to convert and control electrical power with exceptional precision. The device operates by transforming standard AC power into high-frequency DC current, enabling precise control over the welding process. Unlike traditional transformers, these welders incorporate advanced semiconductor technology that allows for rapid switching and precise current control. The system's intelligent control mechanism continuously monitors and adjusts the welding parameters, ensuring optimal performance across various materials and thicknesses. These welders typically feature multiple welding modes, including MIG, TIG, and stick welding capabilities, making them versatile tools for both professional and industrial applications. The compact design, achieved through the elimination of heavy transformers, makes these units significantly more portable than traditional welding machines. Additionally, the IGBT technology enables these welders to operate with improved energy efficiency, reducing power consumption while maintaining superior welding performance. The digital control interface allows users to precisely adjust welding parameters, ensuring consistent quality across different welding applications.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LT

LT UK

UK SQ

SQ HU

HU TH

TH TR

TR FA

FA AF

AF CY

CY MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY