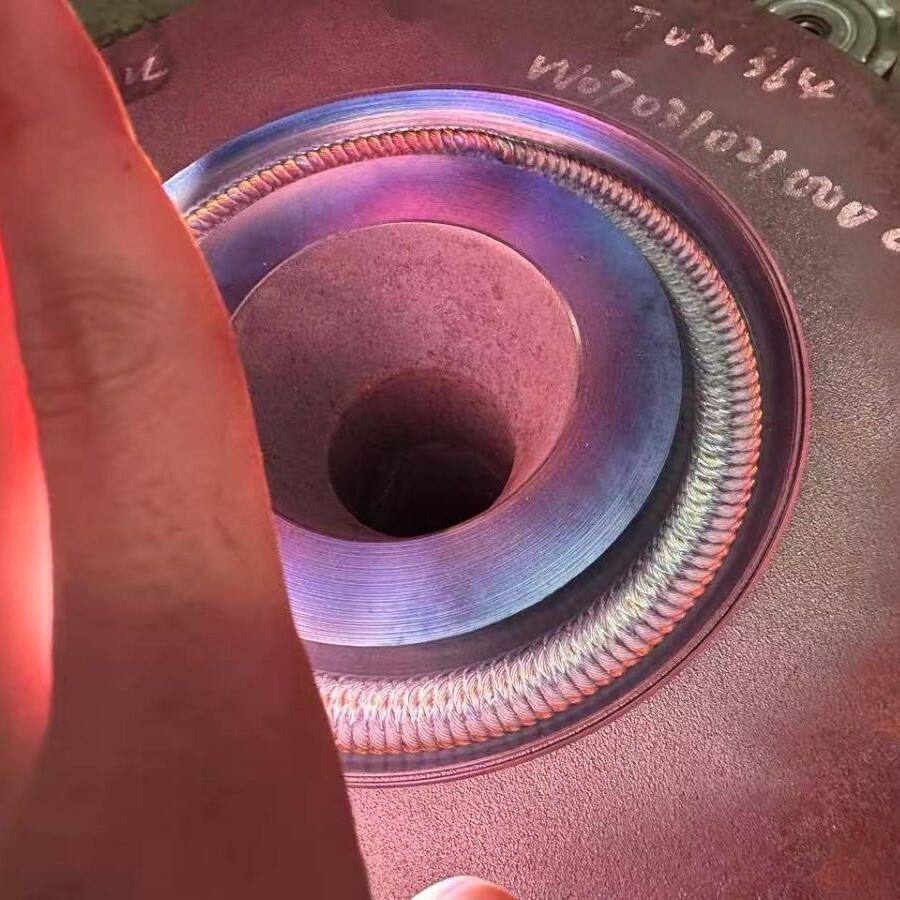

igbt welding machine

The IGBT welding machine represents a significant advancement in welding technology, incorporating Insulated Gate Bipolar Transistor (IGBT) technology to deliver precise and efficient welding operations. This modern welding equipment utilizes advanced power control systems to regulate current and voltage with exceptional accuracy, resulting in superior weld quality and consistency. The machine operates by converting AC power to DC power through IGBT modules, allowing for smoother power output and reduced spatter during welding processes. Its sophisticated control system enables real-time monitoring and adjustment of welding parameters, ensuring optimal performance across various materials and thicknesses. The IGBT welding machine is particularly notable for its versatility, capable of handling multiple welding processes including MIG, TIG, and stick welding. The equipment features intelligent temperature control systems that prevent overheating and maintain stable operation during extended use. With its compact design and user-friendly interface, the machine offers both portability and ease of operation, making it suitable for both industrial applications and smaller workshop environments. The integration of IGBT technology also results in significant energy savings compared to traditional welding machines, while maintaining high power efficiency and reliable performance.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LT

LT UK

UK SQ

SQ HU

HU TH

TH TR

TR FA

FA AF

AF CY

CY MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY