igbt welding machine price

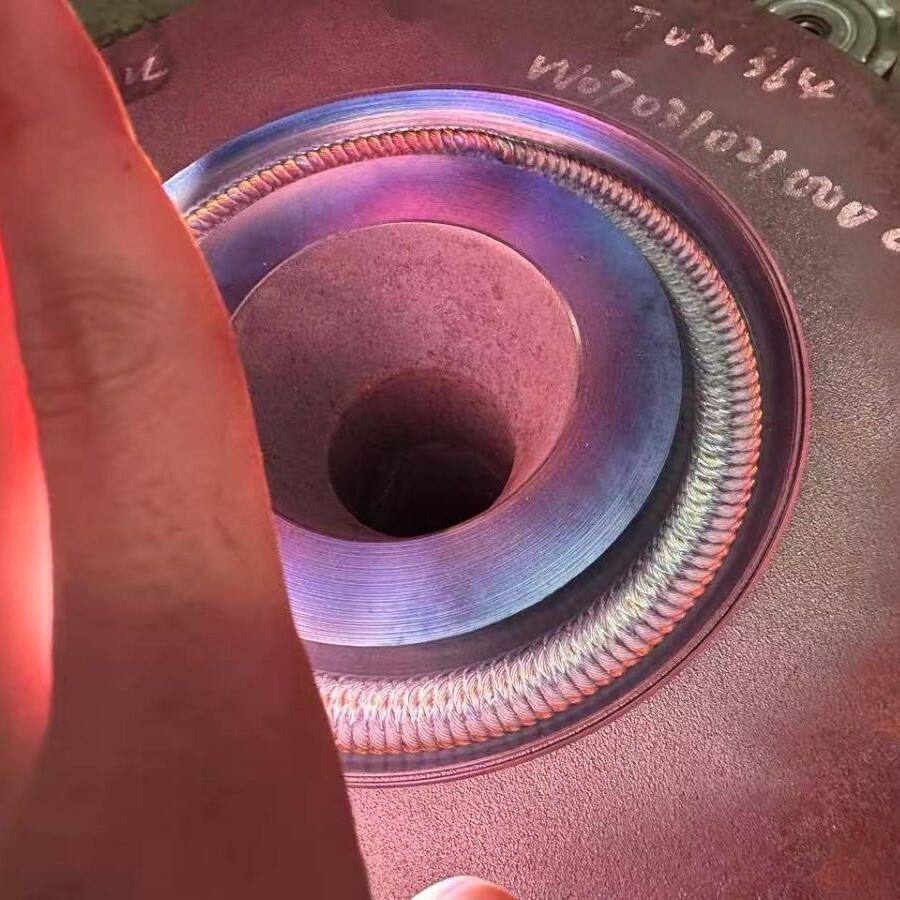

The IGBT welding machine price represents a significant consideration in modern welding technology, offering an optimal balance between cost and performance. These machines utilize Insulated Gate Bipolar Transistor technology, which delivers superior welding control and efficiency compared to traditional welding equipment. When examining IGBT welding machine prices, customers typically find them more cost-effective in the long run due to their reduced power consumption and maintenance requirements. The price range varies depending on specifications, typically starting from $300 for basic models and extending to $3000 for advanced industrial units. These machines feature precise current control, automatic voltage compensation, and intelligent temperature monitoring systems. The investment in an IGBT welding machine is justified by its versatility across various welding applications, including MIG, TIG, and stick welding processes. The pricing structure often reflects additional features such as dual voltage capability, digital displays, and portable designs, making them suitable for both professional workshops and DIY enthusiasts.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LT

LT UK

UK SQ

SQ HU

HU TH

TH TR

TR FA

FA AF

AF CY

CY MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY