igbt inverter welding machine

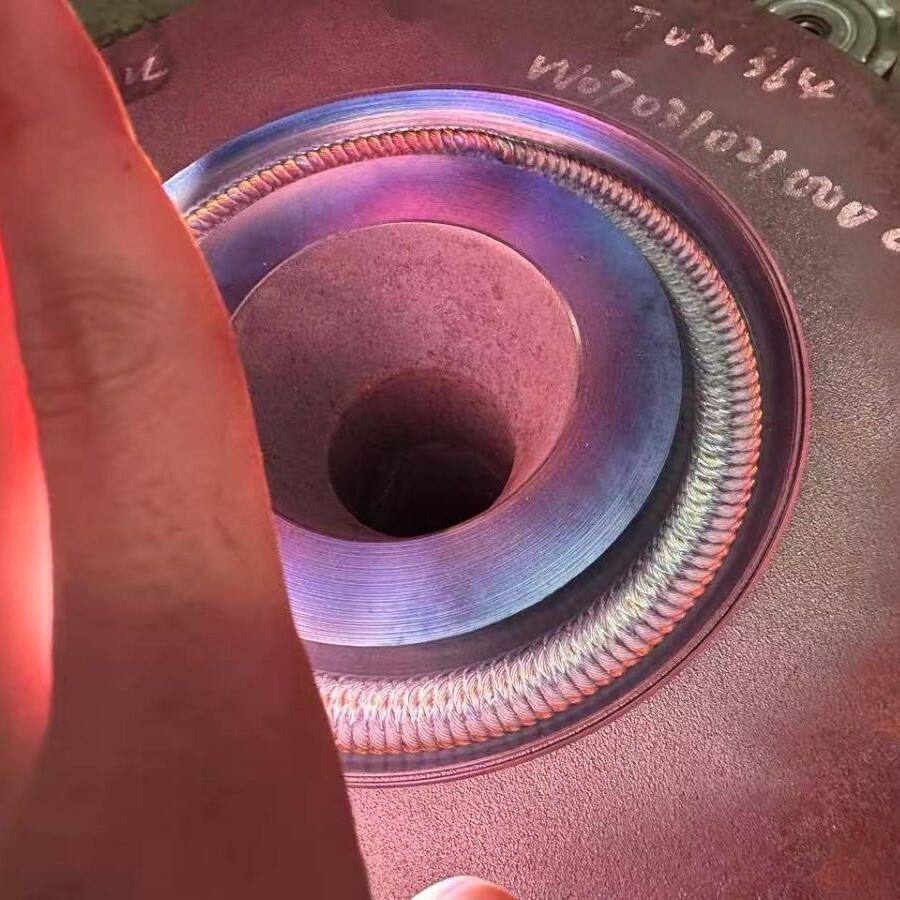

The IGBT inverter welding machine represents a significant advancement in welding technology, combining sophisticated electronic control with exceptional performance capabilities. This modern welding equipment utilizes Insulated Gate Bipolar Transistor (IGBT) technology to convert and control electrical power efficiently, resulting in superior welding quality and reduced energy consumption. The machine operates by converting high-voltage alternating current into direct current, then utilizing IGBT modules to create high-frequency alternating current for precise welding control. This advanced system enables accurate control of the welding parameters, including current, voltage, and arc characteristics. The machine supports multiple welding processes, including MIG, TIG, and stick welding, making it versatile for various applications across industries. Its compact design and lightweight construction make it portable and suitable for both workshop and field operations. The digital control interface allows for precise parameter adjustments, while built-in protection systems safeguard against common welding issues such as overheating and voltage fluctuations. The machine's intelligent control system maintains stable arc performance and automatically compensates for power supply variations, ensuring consistent weld quality regardless of input power conditions.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LT

LT UK

UK SQ

SQ HU

HU TH

TH TR

TR FA

FA AF

AF CY

CY MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY