Enhanced Corrosion and Wear Resistance with TIG Weld Overlay

Superior Protection in Harsh Environments

TIG weld overlay has excellent corrosion resistance making material well suited for parts in contact with aggressive chemicals and environments. This method can reduce the rate of corrosion by about 90 percent, substantially prolonging the life of the parts relative to untreated materials. This improvement is especially beneficial in industries such as the petrochemical, where equipment comes into contact with corrosive agents regularly. Additionally, TIG cladding provides excellent wear resistance meaning they are also suitable for mining and heavy machinery applications. This two-in-one capability enables the parts to withstand harsh environments, without experiencing wear-resisting damage.

Material Versatility for Customized Solutions

These characteristics make TIG weld overlays highly versatile in terms of materials and modifications so that welding can be tailored to individual application requirements. With the ability to adhere to a multitude of substrates, they enable automotive and aerospace manufacturers to tailor performance and durability. For example, the use of fillers can be tailored to control specific properties, for example wear resistance or toughness, for various operating environments. It is this flexibility that makes TIG weld overlays an ideal solution to manufacture customised components designed to withstand challenges found in different industries. This flexibility allows manufacturers to optimize performance for specific applications.

Cost-Effectiveness and Long-Term Savings

Reduced Material Replacement Costs

The application of a TIG weld overlay can decrease the cost of component replacement materials, making it an attractive option for industries aiming to increase the life of their components. Parts last longer, meaning replacements are less frequent. In reality, certain sectors have seen replacement parts' expenditures slashed by half and long term savings have accrued. Businesses can also reduce the incidence of and cost of repairs by investing in TIG cladding, thus affecting their maintenance budgets overall.

Minimized Downtime for Industrial Operations

Tough TIG overlays make the components wear longer, and cut down on operating downtime for repairs, which in turn greatly improve industrial efficiency. Downtime is expensive and disruptive to all production lines. Reducing such breaks can free up resources to work more effectively and generate a higher rate of return. Latest analytics show downtime can be improved by 30% overall, enhancing the strategic importance of considering TIG cladding during maintenance operations. Not only does this efficiency enhance productivity, it helps to secure the business's competitive advantage.

Precision and Quality in Industrial Applications

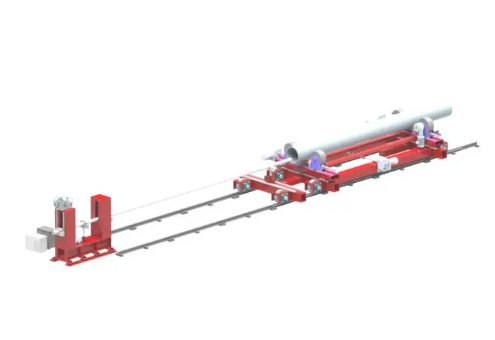

Automated TIG Systems for Consistent Results

Robotic TIG welding systems are also critical for maintaining tight tolerances in industrial applications, especially with high volume production runs. They restrict variation in weld quality, a requirement to preserve manufactured part integrity. Automation increases reproducibility, ensuring that companies can make the same high-quality product over and over again following rigorous guidelines. This reliability is demonstrated with quality control data from automated TIG systems showing substantial improvements in defect rates. As a result, they realize less rework and greater productivity gains.

Low Dilution Rates for Optimal Metallurgical Properties

TIG welding process is the well known and selected; welding process as a cladding proccess characterized by low dilution rates, it's contribute essentially to conserve of the base material chemical properties. This allows the metallurgical characteristics of the part to be unaffected and results in improved strength and crack resistance. Literature survey suggests that low dilution in welding provides extended life on weld joints, which in turn improves performance and life of welded members under service conditions in industries. This emphasis on perfect metallurgical properties highlights how TIG systems can contribute to delivering high quality and resistant products.

Industry-Specific Applications of TIG Cladding Systems

Oil and Gas Pipeline Durability

TIG cladding their importance to the oil and gas industry. Such systems are important to protect pipelines from the rigors to which they are subject. Research demonstrates that pipelines with TIG have significantly lower operation failures and much more longer in service life than those without this protection. Development of TIG overlays may help ensure that corrosion does not prevent the safe and reliable transport of fuels. Significantly better on the bottom line for oil and gas companies with less maintenance and safer work environment.

Power Plant Component Protection

In power plants the TIG weld overlay is used to protect key power plant components, so as to protect them from theabrasive and corrosive wear effects of temperature and pressure. The use of TIG cladding on power plant equipment results in longer operating periods between maintenance shutdowns, which means reduced downtime and costs. Several investigations illustrate the reliability of TIG coatings and parts which are reinforced by this coatings do not fail, which improves the stability and performance of power plant. As unexpected breakdowns are minimized, power plants can operate at a constant level of energy production, which has the effect of ensuring their production targets, economic survival and so on.

Advantages Over Alternative Cladding Methods

Comparison with MIG and Laser Cladding

The choice of the cladding methods is important to achieve long term durability and good performance in industrial environments. Compared with other processes such as MIG and laser cladding, TIG cladding has its own unique advantages. For a start, TIG welding allows users to better control input heat, providing a greater degree of accuracy and more consistent weld quality. This makes it particularly useful for processes that demand extremely precise control of the bonding process. Second, first costs may be more expensive for TIG welding when compared to some of its alternatives, however, the long-term cost-benefits make it more than worthwhile. Less Repairs: TIG welds are stronger, resulting in fewer repairs and a cost savings in the long run. Industry professionals often focus on the robust and higher strength nature of TIG welds over MIG or laser cladding choices.

Flexibility in Complex Geometries

One of the greatest benefits of TIG welding is its ability to handle the most complex of geometries and designs. TIG welding is accurate and is often used for projects that require a high level of engineering or special shapes. The flexibility also ensures compatibility and interface into a multitude of other proprietary equipment and custom machinery. Several case studies have shown the effectiveness of TIG application on complex geometrical shapes and modal analysis for advanced engineering problems. This level of flexibility is essential to custom parts production in industries that regularly process differently shaped parts, in order to ensure that they perform and hold up over time. Also, the possibility to control the welding energy and generate accurate and highly durable overlayers puts TIG cladding ahead of other cladding processes in complex geometries.

FAQ

What is TIG weld overlay?

TIG weld overlay is a welding process used to provide protective coatings on components to enhance corrosion and wear resistance, particularly in harsh environments.

Why is TIG welding considered superior for corrosion resistance?

TIG welding provides a controlled welding environment that limits the dilution of the base metal, preserving its chemical properties and enhancing corrosion resistance.

Can TIG welding be used on all types of metals?

Yes, TIG welding is versatile and can be applied to various base materials, making it suitable for different industrial applications.

How does TIG welding compare to MIG and laser cladding in terms of cost-effectiveness?

While TIG welding may have higher initial costs, its long-term benefits, including reduced maintenance and repair costs, make it a cost-effective solution compared to MIG and laser cladding.

What industries benefit most from TIG weld overlay?

Industries like petrochemicals, mining, oil and gas, and power plants benefit significantly from TIG weld overlay due to its enhanced protective properties against corrosion and wear.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LT

LT UK

UK SQ

SQ HU

HU TH

TH TR

TR FA

FA AF

AF CY

CY MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY