Understanding the Power of Modern Pipe Connection Technology

In the world of industrial pipe joining, the butt fusion welding machine has revolutionized how we create durable, leak-proof connections. This sophisticated technology has become an indispensable tool across multiple industries, from gas and water distribution to chemical processing plants. By utilizing heat and pressure to join polyethylene pipes, these machines create seamless, robust connections that often outlast the pipes themselves.

The significance of reliable pipe connections cannot be overstated in today's demanding industrial environments. As infrastructure projects grow in scale and complexity, the need for dependable joining methods becomes increasingly critical. The butt fusion welding machine answers this call by providing consistent, high-strength welds that maintain structural integrity under various operating conditions.

The Science Behind Butt Fusion Technology

Heat Fusion Process Fundamentals

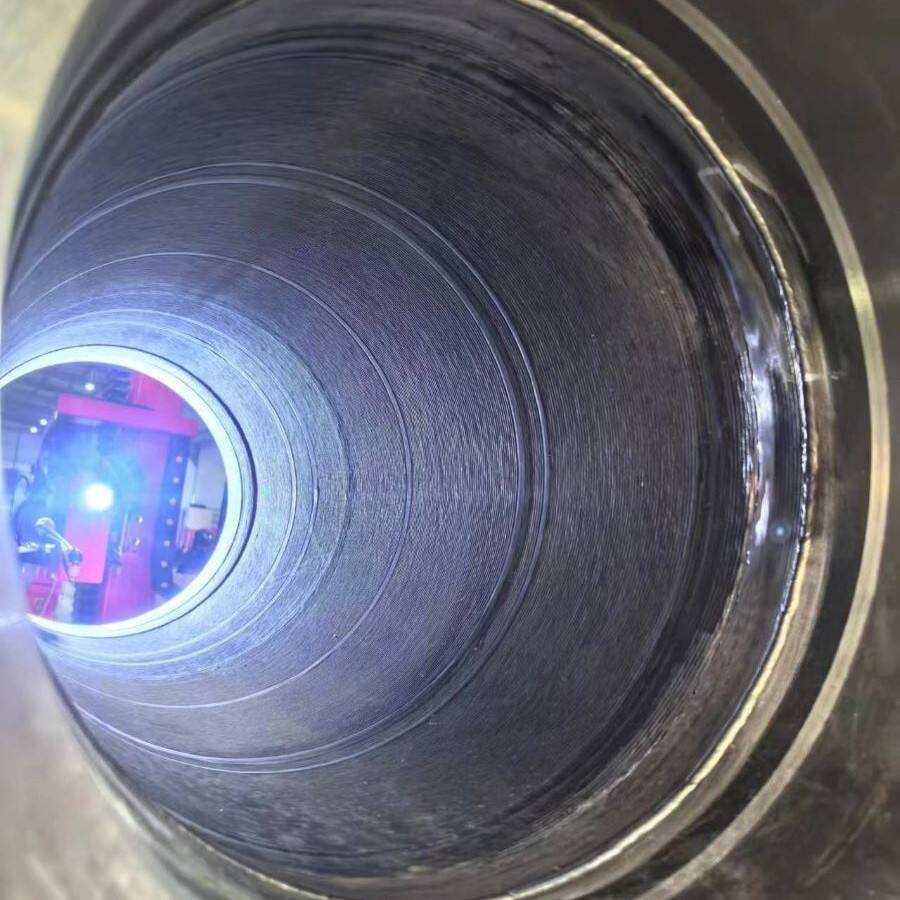

At its core, the butt fusion welding machine operates on a precisely controlled heating process. The system brings pipe ends to a specific temperature, typically between 400°F and 450°F, creating a molten state where the molecular chains of the polyethylene can intermingle. This carefully managed thermal cycle ensures optimal fusion conditions, resulting in joints that are as strong as the original pipe material.

The process involves several critical stages: facing the pipe ends to ensure perfect alignment, heating them to the precise temperature, and applying controlled pressure to create the fusion bond. Modern butt fusion welding machines automate these steps, reducing human error and ensuring consistent results across hundreds or thousands of joints.

Material Compatibility and Performance

While primarily designed for polyethylene pipes, butt fusion welding machines can handle various thermoplastic materials. The technology excels with high-density polyethylene (HDPE) pipes, which are increasingly popular in water and gas distribution networks. The molecular structure of these materials allows for complete fusion, creating a homogeneous joint that resists both internal and external stresses.

The versatility of butt fusion extends to different pipe sizes and wall thicknesses, making it adaptable to diverse project requirements. Modern machines can accommodate pipes from small diameters to massive industrial-scale conduits, maintaining consistent weld quality regardless of size.

Advanced Features of Modern Fusion Equipment

Automation and Control Systems

Today's butt fusion welding machines incorporate sophisticated control systems that monitor and adjust every aspect of the welding process. Digital interfaces provide real-time feedback on critical parameters such as temperature, pressure, and fusion time. This level of automation ensures that each joint meets stringent quality standards while maintaining high productivity levels.

The integration of data logging capabilities allows operators to track and document every weld, creating a comprehensive record for quality assurance and regulatory compliance. Some advanced systems even offer remote monitoring capabilities, enabling supervisors to oversee multiple welding operations from a central location.

Safety and Efficiency Innovations

Modern butt fusion welding machines feature numerous safety enhancements that protect both operators and equipment. Automatic shutdown systems prevent overheating, while ergonomic designs reduce operator fatigue during extended use. These safety features contribute to both worker well-being and overall project efficiency.

The latest machines also incorporate energy-efficient heating elements and smart power management systems, reducing operational costs while maintaining optimal performance. Quick-change components and tool-less adjustments minimize downtime between welds, maximizing productivity on time-sensitive projects.

Field Applications and Success Stories

Infrastructure Development Projects

Across major infrastructure initiatives, butt fusion welding machines have demonstrated their value in creating reliable pipeline networks. Municipal water systems benefit from the corrosion-resistant properties of fusion-welded HDPE pipes, while gas distribution networks rely on the technology's ability to create leak-proof connections that maintain integrity under varying pressure conditions.

Large-scale projects often require thousands of joints to be completed within strict timelines. The efficiency and reliability of butt fusion welding machines make them ideal for such demanding applications, consistently delivering high-quality connections while meeting project schedules.

Industrial Processing Applications

In chemical processing facilities and industrial plants, butt fusion welding machines play a crucial role in creating secure pipework for aggressive materials. The technology's ability to produce joints that resist chemical attack and maintain structural integrity under extreme conditions makes it invaluable in these demanding environments.

The mining industry has also embraced butt fusion technology for slurry transport systems, where pipe connections must withstand abrasive materials and high operating pressures. The robust nature of fusion-welded joints provides extended service life and reduced maintenance requirements.

Future Developments and Industry Trends

Smart Technology Integration

The future of butt fusion welding machines lies in increased connectivity and smart features. Manufacturers are developing systems with advanced IoT capabilities, enabling real-time monitoring, predictive maintenance, and seamless integration with project management platforms. These innovations will further enhance efficiency and quality control in pipeline construction projects.

Artificial intelligence and machine learning algorithms are being incorporated to optimize welding parameters automatically, adapting to varying environmental conditions and material properties. This level of automation will reduce the reliance on operator expertise while maintaining consistently high-quality results.

Environmental Considerations

As sustainability becomes increasingly important, butt fusion welding machines are evolving to reduce their environmental impact. Newer models feature improved energy efficiency and reduced carbon footprints, aligning with global initiatives for greener construction practices. The long-term durability of fusion-welded joints also contributes to environmental conservation by minimizing the need for repairs and replacements.

The industry is also exploring eco-friendly heating technologies and renewable power sources for fusion equipment, demonstrating a commitment to environmental stewardship while maintaining high performance standards.

Frequently Asked Questions

What maintenance is required for a butt fusion welding machine?

Regular maintenance includes cleaning the heating element, checking hydraulic fluid levels, calibrating temperature controls, and inspecting mechanical components for wear. Most manufacturers recommend professional servicing annually, along with daily cleaning and inspection routines to ensure optimal performance and longevity.

How long does a typical butt fusion joint take to complete?

The duration varies based on pipe size and wall thickness, but typically ranges from 15-45 minutes for smaller diameters (up to 12 inches) and can extend to several hours for larger pipes. This includes heating time, cooling period, and necessary preparation steps to ensure a proper fusion bond.

What training is needed to operate a butt fusion welding machine?

Operators should complete a certified training program covering machine operation, safety procedures, and quality control measures. This typically includes both classroom instruction and hands-on practice. Many manufacturers and industry organizations offer certification programs that meet international standards for fusion welding competency.

EN

EN

AR

AR BG

BG HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LT

LT UK

UK SQ

SQ HU

HU TH

TH TR

TR FA

FA AF

AF CY

CY MK

MK LA

LA MN

MN KK

KK UZ

UZ KY

KY